By definition, actuators either move things or stop them. In industrial design and other heavy-duty applications, actuators (also called cylinders) provide the driving force that moves or holds machinery components. Linear actuators work by converting energy from a power source into straight-line motion, forward and/or back. Depending on your application, the energy source you use may be hydraulic (fluid-based), pneumatic (air pressure-based), or even electric. You can read more about when it is appropriate to use electric actuators here. For now, we’re delving into the main differences between hydraulic and pneumatic actuators and their distinctive advantages and disadvantages.

Comparing Hydraulic and Pneumatic Cylinders

Hydraulic Actuators

Hydraulic actuators can give you the greatest power and torque because hydraulic fluid can achieve very high pressures consistently. This is essential for operating heavy construction equipment or holding an elevator, for example, but these cylinders are also a good choice for other instances where brute force is required. Hydraulic power also tends to provide smooth, consistent motion along the entire stroke, which can be crucial in some applications.

Pros

- Can deliver up to 25 times the force of same-size pneumatic cylinders

- Offer a higher horsepower-to-weight ratio

- Hold force without the continuous application of fluid pressure from the power source

- Can more readily be used within a closed system because fluids are not compressible like air

Cons

- Seals wear and can leak, inviting contamination that can cause damage to internal or external working parts or to products being manufactured

- Require multiple associated parts–motors, pumps, fluid reservoirs, etc.–in order to work, increasing maintenance time and cost

- Often very noisy, even when outfitted with noise-reduction equipment

- Don’t perform well in extreme temperatures, which alter the fluid viscosity

These factors can make hydraulic actuators too unwieldy and unrealistic for many environments.

Pneumatic Actuators

Pneumatic actuators are driven by air pressure rather than fluid. These are the most versatile workhorses among actuators, a good choice for a wide variety of movements where high torque, precise linear movements, and/or no-fail holding power are required, even at high speeds.

Pros

- More affordable and more readily available than hydraulic systems

- Air compressors are common in man industrial settings, so there is a ready power source to operate cylinders

- More efficient and can operate at much higher cycle speeds than hydraulic actuators Withstand harsh washdown environments that can present problems for other types of cylinders

- Performance is less affected by extremely high or low temperatures

- Approved for food processing applications

- With no motor or hazardous materials, they can easily meet mechanical safety requirements

- Come in a multitude of sizes, styles, and configurations.

- Fewer associated components make them much easier to integrate into your overall design

- Easier and less costly to maintain -- overall operating costs are lower for pneumatic-style cylinders

Pneumatic actuators operate at lower pressures and speeds than hydraulic cylinders. For many applications, though, this is an advantage because you can achieve finely tuned, consistent control. To achieve maximum efficiency, it is important to size pneumatic actuators accurately for the job at hand.

Cons

- Can sometimes be less efficient as a power source because the air compressor that powers a pneumatic actuator must be located relatively close by, and its reservoir must hold enough volume to avoid the risk of running continuously

- Air can become contaminated by equipment lubricants, increasing the risk of damage, although there are preventative measures you can take to reduce this risk

- Usually limited to 100-200 psi so they can generate only limited force

Because air can be compressed, there is a risk that pressure applied to the cylinder may not be perfectly consistent. Though not always a critical factor, this can be vitally important for certain applications.

Types of Actuators

Branham manufactures several different types of pneumatic actuators, each available in a variety of bore sizes:

- MAGTEC® - Magnetically Coupled-Type

- pneU-SA® - Enclosed Cable-Type

- DURATRK™ - Band-Type

- OVLPRO™ - Low Profile Rod Air

Our MAGTEC line features rodded magnetically coupled-type cylinders. Their unique design takes advantage of non-welded tubing and heads, which makes the cylinders refurbishable instead of needing to be disposed of and replaced. Additionally, MACTEC cylinders have completely enclosed actuator bodies that prevent contaminants from penetrating them. These cylinders are ideal for demanding, wet, or harsh environments, such as food processing.

The OVLPRO is a unique Branham innovation -- a rod cylinder with an oval bore instead of the usual round shape. This eliminates risk of rotation during extension and retraction, making this particular model a sound choice for applications where consistent precision is critical. The low-profile OVLPRO comes in two sizes with multiple configurations.

In addition, Branham is proud to be the sole distributor of Artec ISO and UNITOP pneumatic cylinders in the US and Canada. These products meet such strict international standards regarding size, materials, and durability.

Sometimes, however, hydraulic linear actuators are the best solution. They are available in rodded and cable designs. Each type has advantages and limitations, so the key to successful performance is, as always, matching the cylinder with the task at hand.

Choosing the Right Actuator

Even though there are distinct differences between pneumatic and hydraulic cylinders, there are also a lot of variables to consider since every industrial design project is unique in its requirements and challenges. Key factors include load type, speed, frequency, torque, precision and holding power required, and the working environment.

Remember the story of the tortoise and the hare? Think of a hydraulic cylinder as the tortoise — not the fastest tool around, but reliably tough and strong. A pneumatic cylinder would be the hare — faster and more agile, but not the right tool when you need major muscle. That may be all you need to know to determine whether hydraulic or pneumatic is the better way to go.

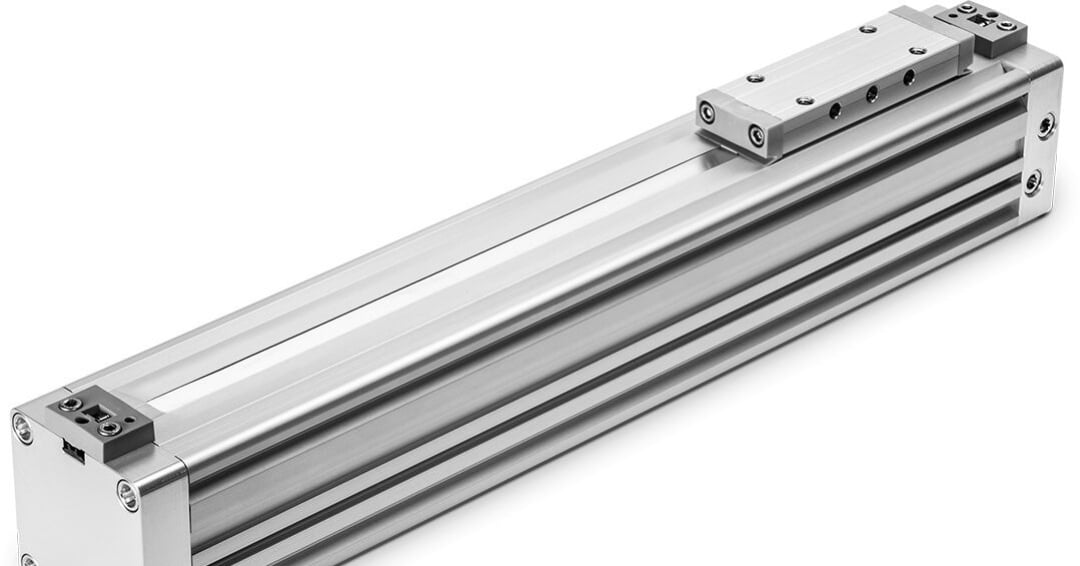

However, stroke length can also be the determining factor. If your application requires a stroke length greater than 24 inches but the operating envelope is compact because of space limitations (a common challenge), a rodless cylinder is a much better choice. That’s because rodless cylinders move their stroke over the body of the cylinder, whereas rod cylinders extend their stroke outside the body. Rodless cylinders can also achieve a stroke length over 20 feet compared to just 2 to 3 feet for a rod cylinder.

We’re Here to Help

Whether you choose pneumatic or hydraulic cylinders, it is critical that you make the right decision during the design process. Once the equipment is in place, it will be expensive to change your mind. So, are you ready for that consultation phone call?