When your industrial design calls for linear movement, you might want to use hydraulic actuators. There are definite advantages to using a fluid-powered actuator, but that doesn’t mean they are right for every purpose. It all comes down to the requirements of your specific application. So, when should you choose hydraulic linear actuators?

When your industrial design calls for linear movement, you might want to use hydraulic actuators. There are definite advantages to using a fluid-powered actuator, but that doesn’t mean they are right for every purpose. It all comes down to the requirements of your specific application. So, when should you choose hydraulic linear actuators?

Hydraulic Linear Actuators for High Force

The most common reason is when you require high force. Even small hydraulic actuators can exert tremendous force. For example, a rod-style hydraulic linear actuator can produce up to 5,000 psi, whereas a pneumatic linear actuator would typically deliver between 100-200 psi.

This is why heavy duty machinery such as construction equipment uses hydraulic actuators. Rod-type hydraulic cylinders are also used on car transport carriers, where it takes a terrific amount of pressure for cylinders to raise and lower vehicles into position. In agriculture, hydraulic actuators are on the job raising and lowering plow blades, just to name a few applications.

But powerful thrust isn’t the only reason to choose a hydraulic model.

Advantages of Hydraulic Linear Actuators

These actuators are a good choice when:

-

The movement you need to control is simple, without speed changes or multiple stops and starts.

-

You cannot afford “wiggle room.” There is no give in hydraulic pressure because it is virtually impossible to compress fluid, so hydraulic actuators can maintain force and torque steadily. For applications that require smoother travel, a cable-style, low-pressure hydraulic actuator may be the best choice.

-

For instance, if you need to raise and lower the platform on a parts elevator, smooth travel is essential. When the platform stops, a hydraulic actuator will hold it stationary. If you were to use a pneumatic actuator, any slight change in air pressure could cause the platform to move a little. Another good example is when you need to spray a smooth, uniform coating on a part.

-

-

The operating environment includes harsh conditions. Hydraulic actuators are both durable and reliable under duress, including shock loads. This is why you often see them used for outdoor applications. That said, in some working environments, temperature extremes can affect hydraulic performance either by causing premature seal failure or changing the viscosity of the hydraulic fluid.

Disadvantages of Hydraulic Linear Actuators

Of course, hydraulic linear actuators are not always the best choice for your application. Disadvantages of this type of actuator include:

-

You need a specialized sensor to monitor and gather data from a hydraulic actuator. In some industries, manufacturing processes must be documented as part of quality assurance or continuous improvement programs, but the actuator can't provide that data on its own. So, you would need a separate sensor.

You need a specialized sensor to monitor and gather data from a hydraulic actuator. In some industries, manufacturing processes must be documented as part of quality assurance or continuous improvement programs, but the actuator can't provide that data on its own. So, you would need a separate sensor. -

Hydraulic actuators are not electronically programmable. That means any adjustments cannot be automated but must be done manually, which invites a lack of precision.

-

Hydraulic components tend to be noisy, which can be a factor in some operating environments.

-

Hydraulic actuators are expensive to maintain. Hydraulic actuators may be affordable up front, but there are more moving parts associated with their operation. This means repairs are more likely and more expensive to fix. For example, worn seals can leak, damaging the actuator and potentially contaminating the working environment.

Best Applications for Hydraulic Linear Actuators in Industrial Environments

Based on their inherent strengths and weaknesses, hydraulic linear actuators are typically best for applications such as:

-

Opening and closing damper doors

-

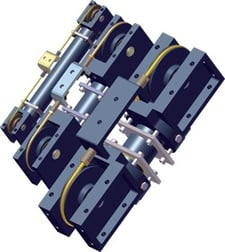

Clamping

-

Welding

-

Presses

But, before selecting a hydraulic linear actuator, you may want to consider a pneumatic actuator instead. In many cases, pneumatic actuators are actually a better option since compressed air is readily available on factory floors.

Pneumatic Actuators Are Often the Best Choice

Pneumatic components can function at lower pressures and higher speeds than hydraulic components. In this case, pneumatic linear actuators are a better choice. They can reliably and accurately move loads to tolerances within 0.1 inches. They can achieve repeatability tolerances within .001 inches. And extreme temperatures do not affect their performance with the right sealing choice. They also are more affordable, have lower operating costs, are more sanitary, and are available with many design styles and mounting arrangements for just about every industrial use.

Pneumatic components do require an air compressor that runs continuously and is located near enough to maintain desired air pressure. W.C. Branham makes both pneumatic rodless cable cylinders — ideal for low-pressure applications — and our DURATRK® line of pneumatic rodless cylinders. Also, check out our OVLPRO® series of low pressure rod cylinders and MAGTEC® Magnetically Coupled Rodless Cylinders.

Pneumatic components do require an air compressor that runs continuously and is located near enough to maintain desired air pressure. W.C. Branham makes both pneumatic rodless cable cylinders — ideal for low-pressure applications — and our DURATRK® line of pneumatic rodless cylinders. Also, check out our OVLPRO® series of low pressure rod cylinders and MAGTEC® Magnetically Coupled Rodless Cylinders.

Need more help deciphering whether hydraulic linear actuators or a pneumatic style would be best for your application? Just ask. We’re always ready to help.

Editor's Note: This post was originally published in 2018 and has been updated for accuracy as of May 2021.