Model Selection & Configuration

What OVLPRO models are available?

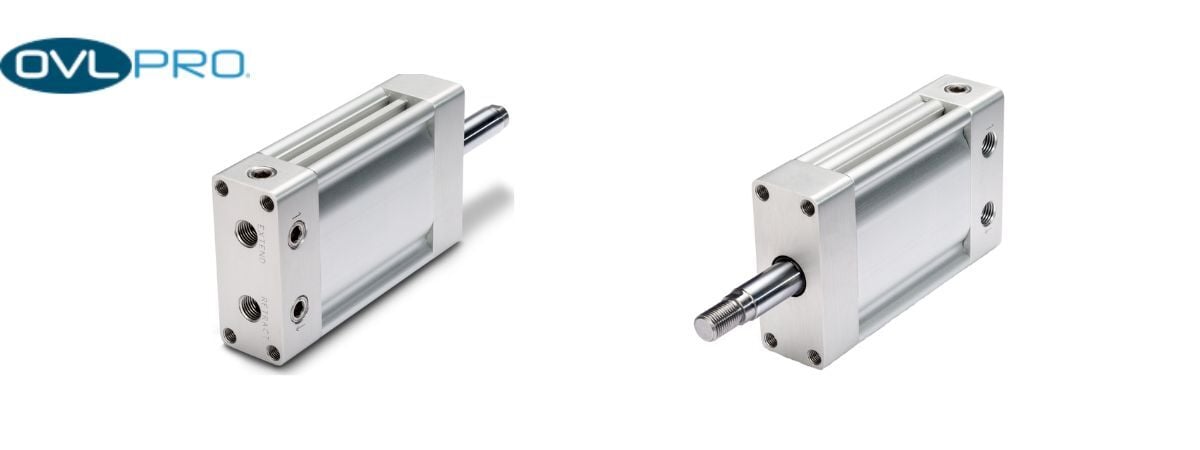

The OVLPRO line is available in three bore sizes designed for applications requiring precision control in compact spaces: OVP25 (25mm bore), and OVP44 (44mm bore).

All models feature an extruded high-strength aluminum body with an oval piston bore. The oval design prevents rod rotation during extension and retraction, eliminating a common characteristic in round-bore cylinders.

Standard product includes integrated T-slots and piston magnets for sensor compatibility, mounting flexibility, and multiple porting options.

Learn about OVLPRO applications

How do I choose the right bore size for my application?

Bore selection depends on required output force at your operating pressure. OVLPRO cylinders operate at pressures up to 200 PSI, though typical industrial applications run at 80-100 PSI.

Selection process:

- Calculate required force: Load weight × coefficient of friction for your guiding mechanism

- Account for differential force between extend and retract strokes (rod side has less effective area)

- Compare both extend and retract forces against bore size capacity at available pressure

- Verify stroke length compatibility with selected bore size

- Check that maximum load versus stroke length falls within specifications - minimize moment loads for longer stroke lengths.

For horizontal sliding applications, use the force calculation above. For applications where the cylinder both supports and guides the load, compare load and stroke length requirements to ensure they fall within guidelines. Excessive loading at longer stroke lengths creates bending pressure on the rod that can cause binding or seal failure.

Contact us for sizing assistance

What stroke lengths are available for OVLPRO cylinders?

OVLPRO cylinders accommodate custom stroke lengths in any increment:

- OVP25: Up to 12 inches maximum stroke (contact Branham should your application require longer lengths)

- OVP44: Up to 12 inches maximum stroke (contact Branham should your application require longer lengths)

Common stroke lengths are stocked for quick make-to-order availability. Contact Branham for lead times of custom stroke lengths.

The ability to specify stroke in any increment eliminates the need to compromise on design dimensions or accept a cylinder that extends beyond required travel distance.

What configuration options are available?

Bore sizes: 25mm and 44mm

Stroke lengths: Any increment up to the maximum standard stroke (12 inches for OVP25, 12 inches for OVP44). Custom longer strokes are available upon request.

Rod options:

- Male threaded rod

- Female threaded rod

- Standard: Chrome-plated steel rod with black oxide fasteners

- MX Series upgrade: Stainless steel hard chrome-plated rod with stainless steel fasteners and hardware

Porting options:

- Rear porting

- Side porting

Sensor options:

- Standard piston magnet for position sensing

- T-Slots for sensor-ready configuration

Mounting options:

- Can be directly mounted flat or on side

- Flange mounts kits available for front, rear, or side mounting options.

- Horizontal and vertical rear clevis mount kits available

Action:

- Standard: Double-acting (powered stroke in both directions)

- Single-acting customization (power stroke in one direction only) is available as a factory option

The MX Series with stainless steel components provides enhanced durability and protection in corrosive environments, high humidity, or applications with cleaning chemicals and water.

Are OVLPRO cylinders interchangeable with other brands?

No. OVLPRO cylinders are not directly interchangeable with other brands. Although uniquely designed, performance attributes are similar with other brands.

Can OVLPRO cylinders replace round bore cylinders in existing designs?

Yes, in many applications. OVLPRO cylinders offer advantages that make them suitable replacements for traditional NFPA or ISO round bore cylinders when space constraints or precision requirements justify the switch.

Replacement advantages:

- Lower profile body fits in spaces where round bore cylinders don't

- Eliminates rod rotation without requiring external guide rods and guide blocks

- Can be mounted flat or on side for additional space savings

- Provides equivalent force output to comparable bore size round cylinders

- Stackable or side-by-side mounting when multiple cylinders needed

Design considerations:

- Verify mounting interface compatibility using dimensional drawings

- Confirm stroke length requirements fall within OVLPRO maximums (12" for 25mm, 12" for 44mm)

- Calculate forces on both extend and retract strokes for proper sizing

- Compare load and stroke requirements against specifications

OVLPRO's oval bore design delivers the force that an equivalent bore size traditional round cylinder provides, but in a lower profile package without rotation issues.

Learn more about oval bore advantages

Oval Bore Design & Technology

How does the oval bore design prevent rod rotation?

Traditional round cylinders allow slight rod rotation as the piston extends and retracts. An oval piston working in an oval bore cannot rotate by design.

The rotation problem with round cylinders:

Round pistons can shift slightly within their round bore during operation. Even minimal rotation pulls thrust force off-line, reducing performance. Over time, off-center loading causes premature wear on seals and rod bearings, rod bending, or rod de-threading from the piston.

OVLPRO's solution:

The oval cross-section creates physical constraints that prevent any rotation. The piston shape matches the bore geometry precisely, allowing linear movement while blocking rotational movement entirely.

This mechanical solution reduces the need for external guide rods and guide blocks that would otherwise be required to prevent rotation in precision applications.

View OVLPRO technology details

Why is rod rotation prevention important?

In applications requiring consistent precision, even slight rod rotation creates serious problems:

Precision impact:

- Pulls intended thrust force off-line

- Creates inconsistent positioning across cycles

- Compounds small errors in high-cycle operations

Component reliability:

- Accelerates wear on seals and rod bearings through uneven loading

- Increases risk of rod bending under load

- Can cause rod to de-thread from piston, leading to complete failure

Applications in medical device assembly, semiconductor manufacturing, automated assembly, and food processing often cannot tolerate any positioning variation. OVLPRO's oval bore design provides inherent rotation prevention without the added complexity, cost, and space requirements of external guidance systems.

Learn about precision applications

What materials are used in OVLPRO construction?

Standard OVLPRO model:

- Body: High-strength extruded aluminum

- Rod: Chrome-plated steel

- Fasteners: Black oxide

- Seals: Industry-standard pneumatic seals

- Lubrication: Teflon-based grease

OVLPRO MX Series (corrosion-resistant upgrade):

- Body: High-strength extruded aluminum

- Rod: Stainless steel hard chrome-plated

- Fasteners: Stainless steel hardware throughout

- Seals: Industry-standard pneumatic seals

- Lubrication: Teflon-based grease

The Teflon-based lubrication remains stable when exposed to hot surfaces and corrosive moisture, making OVLPRO suitable for challenging industrial environments.

High-strength aluminum construction provides durability while keeping the cylinders lightweight. The extruded body design creates a robust cylinder that is repairable rather than disposable, extending service life and improving return on investment.

Performance & Operating Conditions

What operating conditions do OVLPRO cylinders support?

- Maximum Pressure: 200 PSI (rated capacity)

- Standard Operating Pressure: 80-100 PSI for most industrial applications

- Media: Compressed and filtered air, dry or lubricated

- Temperature Range: The standard operating temperature range is 0°F to +180°F (-18°C to +82°C). Viton® Seals are available as an option for applications requiring higher operating temperatures.

- Lubrication: Teflon-based grease unfazed by hot surfaces and corrosive moisture

OVLPRO cylinders are designed for double-acting operation (powered in both directions) as standard, with single-acting configuration available upon request.

Request technical specifications

How much force can OVLPRO cylinders generate?

Force output depends on bore size and operating pressure.

- OVLPRO25 at 100 PSI: 78 lbs extend force, 67 lbs retract force

- OVLPRO44 at 100 PSI: 241 lbs extend force, 210 lbs retract force.

The difference between extend and retract forces occurs because the rod side has less effective net piston area. This reduction must be accounted for when sizing cylinders.

For OVP32 and OVP44 bore sizes, force calculations follow standard pneumatic cylinder formulas based on effective piston area and operating pressure.

Contact Branham with your application requirements for force calculations specific to your bore size, pressure, and operating conditions.

Use our cylinder force calculator

Can OVLPRO cylinders be stacked or mounted side-by-side?

Yes. OVLPRO's compact design specifically supports stacking and side-by-side mounting to boost thrust power without consuming excessive space.

Multi-cylinder configurations:

- Stack multiple cylinders vertically

- Mount side-by-side for parallel operation

- Combine both approaches in complex assemblies

Advantages:

- Multiply force output without larger individual cylinders

- Create redundant actuation for critical operations

- Fit multiple actuators in constrained spaces

- Maintain compact machinery footprint

The low profile design makes stacking practical where standard cylinders would create excessive height.

A mounting plate accessory is available that integrates OVLPRO cylinders with DURATRK rodless cylinders for Y-axis functionality in pick-and-place material handling applications.

How does OVLPRO's profile compare to round bore cylinders?

OVLPRO cylinders have a lower profile body than traditional NFPA or ISO round bore cylinders of equivalent bore size.

Profile advantages:

- Fits in spaces where round cylinders cannot

- Can be mounted flat or rotated on side for additional space savings

- Reduces overall machinery height when mounted horizontally

- Enables compact designs in space-constrained equipment

The oval cross-section creates a flatter profile while maintaining the effective bore area needed to generate required force. This geometry allows OVLPRO to deliver the same output as an equivalent round bore cylinder but in a package that fits tighter vertical spaces.

For applications where every millimeter matters in machinery profile, OVLPRO's lower height can be the difference between a design that works and one that doesn't.

Reliability & Maintenance

Are OVLPRO cylinders repairable?

Yes. OVLPRO cylinders are repairable, not a throw-away type. They are designed for easy service, with all seals, the rod, rod bearing, and fasteners being replaceable components.

Serviceability features:

- Parts are not welded, allowing disassembly

- Easy in/out access to internal components

- Wearable seals can be replaced as needed

- Standard replacement parts available

- Service extends cylinder life significantly

This repairable design reduces total cost of ownership. Rather than replacing entire cylinders when seals wear, maintenance teams can perform targeted repairs at lower cost and with less downtime.

The robust construction supports repair economics. These are engineered cylinders built for long service life, making repair investment worthwhile compared to disposable alternatives.

Contact us about service and parts

What service life can I expect from OVLPRO cylinders?

OVLPRO cylinders are designed with proper operation and maintenance.

Factors affecting service life:

- Operating within specified pressure range (up to 200 PSI maximum)

- Using filtered, properly conditioned air

- Avoiding excessive side loading or moment loads

- Maintaining proper lubrication

- Operating within load capacity at given stroke length

- Keeping external environment reasonably clean

Design features supporting longevity:

- High-strength extruded aluminum body resists deformation

- Teflon-based lubrication maintains performance in challenging conditions

- Quality seals minimize wear and leakage

- Oval bore design eliminates rotation-related wear

- Repairable construction allows seal replacement before failure

For high-duty cycling applications, pre-lubrication can be specified to extend maintenance intervals and component life.

Does OVLPRO require special maintenance?

OVLPRO cylinders require standard pneumatic cylinder maintenance practices:

- Use clean, filtered compressed air

- Maintain appropriate lubrication (pre-lubricated option available for high-duty cycling)

- Operate within specified pressure and load limits

- Inspect regularly for signs of wear or damage

- Replace seals when leakage occurs

- Avoid contamination of sealing surfaces

The Teflon-based lubrication used in OVLPRO cylinders provides good performance across temperature ranges and resists degradation from environmental factors including hot surfaces and corrosive moisture.

Proper sizing during initial selection is critical to minimize maintenance needs. Cylinders operating within their load and stroke specifications experience significantly less wear than undersized or overloaded units.

Application Suitability

What applications are best suited for OVLPRO cylinders?

OVLPRO cylinders excel in applications where precision positioning, space constraints, and prevention of rod rotation are critical:

Medical Device Manufacturing:

- Automated assembly requiring extreme precision

- Clean room compatibility

- Consistent positioning across millions of cycles

- Space-constrained medical equipment

Semiconductor Manufacturing:

- Ultra-high precision requirements

- Clean environment operation

- High-speed automated assembly

- Stable positioning without rotation

Packaging Machinery:

- Consistent product positioning

- Compact equipment design

- High-cycle operation

- Multiple actuators in tight spaces

Food Processing Equipment:

- Sanitary environment operation (especially MX Series)

- Reliable actuation in presence of moisture

- Compact equipment footprint

- High-duty cycling

Material Handling:

- Precise load positioning

- Conveyor systems with limited vertical space

- Pick-and-place operations (especially with DURATRK cross adapter)

- Automated sorting

Additional applications:

- Automated assembly lines

- Wire machinery

- Bottling and filling systems

- Paper converting machinery

- Ergonomic systems

- Conveying systems

When should I choose OVLPRO over guided round bore cylinders?

Choose OVLPRO when:

- Rod rotation must be eliminated but space doesn't allow external guide rods

- Lower profile package is needed compared to round bore with guides

- Simpler mechanical design is preferred

- Weight reduction matters (guides add mass)

- Cost-effective rotation prevention is required

- Stackable or side-by-side mounting would benefit design

Choose guided round bore cylinders when:

- Extreme moment loads exceed OVLPRO capacity

- Standardization on round bore components is priority

- Guide rod visibility aids troubleshooting

- Higher bore sizes than 44mm are required

OVLPRO provides rotation prevention through its oval bore geometry rather than external guides. This integrated solution reduces parts count, simplifies assembly, saves space, and lowers overall system cost while maintaining precision.

For applications where external guides would be necessary with round bore cylinders, OVLPRO often represents a more elegant and economical solution.

Learn about oval bore advantages

Can OVLPRO handle corrosive or high-moisture environments?

Yes, especially with the OVLPRO MX Series upgrade.

Standard OVLPRO:

- Teflon-based lubrication resists corrosive moisture

- Suitable for moderately challenging environments

- Chrome-plated steel rod provides reasonable corrosion resistance

OVLPRO MX Series (recommended for harsh environments):

- Stainless steel hard chrome-plated rod

- Stainless steel fasteners and hardware throughout

- Enhanced durability in corrosive environments

- Superior performance in high humidity

- Better resistance to cleaning chemicals

- Improved longevity in food processing applications with frequent washdown

For environments with aggressive chemicals, frequent washdown cycles, or severe corrosion potential, specify the MX Series to ensure long service life and minimize maintenance requirements.

Contact us about environment-specific requirements

Are OVLPRO cylinders suitable for clean room environments?

Yes. OVLPRO cylinders are particularly well-suited for medical device and semiconductor manufacturing applications that often require clean room operation.

Clean room advantages:

- Teflon-based lubrication reduces contamination risk

- Sealed design minimizes particle generation

- Non-rotating rod design reduces wear debris

- Quality seals prevent leakage

- Smooth operation limits vibration and particle creation

For ultra-clean environments, consider:

- Regular external cleaning protocols

- Filtered air supply to cylinders

- MX Series with stainless steel components for better cleanability

- Proper sizing to minimize wear and particle generation

Medical device assembly and semiconductor manufacturing represent ideal applications for OVLPRO, where both clean operation and extreme precision are mandatory.

Learn about medical industry applications

Special Features & Integration

How does the DURATRK cross adapter work with OVLPRO?

Branham offers a mounting plate that integrates OVLPRO cylinders with DURATRK rodless cylinders to create Y-axis functionality.

Integration benefits:

- Combines DURATRK X-axis movement with OVLPRO Y-axis actuation

- Ideal for pick-and-place material handling applications

- Affordable alternative to more complex positioning systems

- Compact overall footprint

- Proven compatibility between product lines

This cross adapter mounting works specifically with DURATRK DTF 25 or 40 series rodless cylinders. The combination creates a two-axis positioning system without requiring separate linear guides or complex mounting hardware.

For applications requiring multi-axis actuation in limited space, this integrated solution simplifies design and reduces total system cost while maintaining Branham's quality standards across all components.

Contact us about integration options

What sensor options work with OVLPRO cylinders?

All OVLPRO cylinders come standard with a piston magnet, making them sensor-ready for position feedback.

Standard configuration:

- Integrated piston magnet

- Compatible sensors: reed switch, NPN, and PNP

- Allows position sensing without modifications

- Simplifies installation and wiring

This sensor-ready design eliminates the need to specify special sensor packages or make field modifications. External sensors (reed switch, NPN, or PNP) can be mounted on the T-slot grooves in the extrusion and used to detect piston position at any point along the stroke for position feedback.

The integrated magnet approach is standard pneumatic cylinder practice, ensuring compatibility with widely available sensing devices.

Request sensor recommendations

Ordering & Support

How do I order an OVLPRO cylinder or get support?

Contact W.C. Branham to discuss your application requirements:

- Phone: 1-800-428-1974 (U.S./Canada) or 715-426-2000 (Local)

- Email: AskWCB@wcbranham.com

- Website: www.wcbranham.com