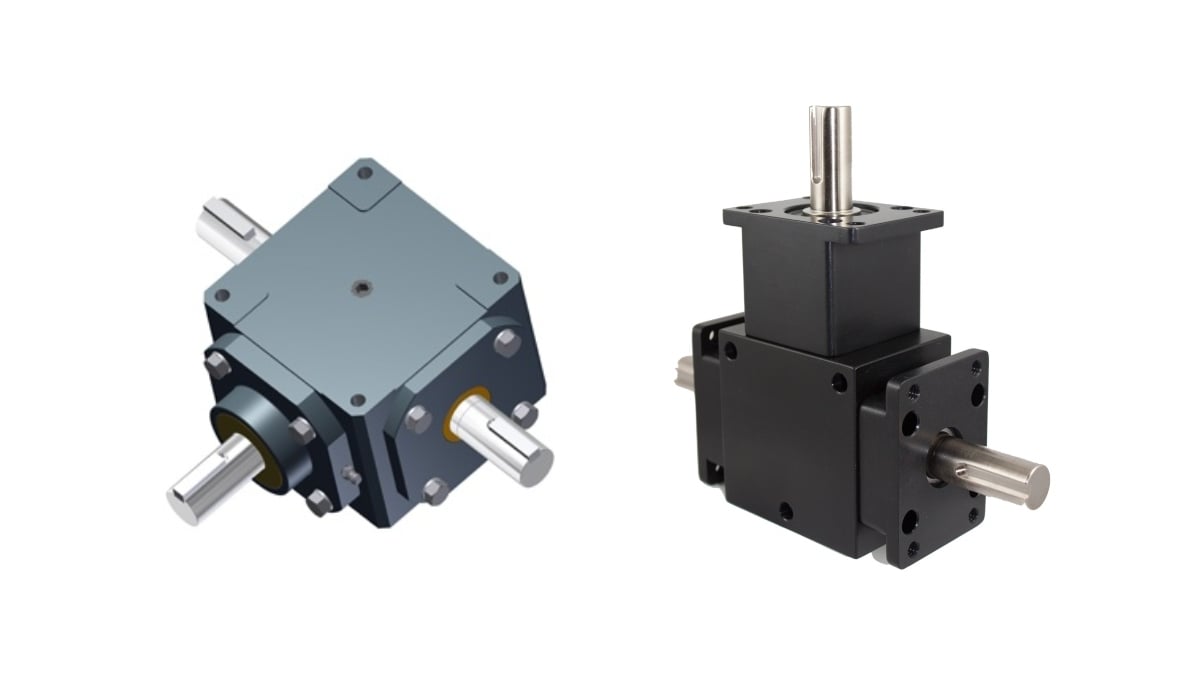

Bevel gears enable us to operate a vast array of machinery, massive or small, so they are indispensable in many industrial applications. A bevel gearbox is particularly useful because, just by the way the components integrate with one another, it can control the speed and amount of power delivered to an output shaft while changing rotational direction.

Usually a bevel gear is conical in shape. The teeth that come together to drive the gear can be arranged straight up and down, or they can be curved to form a spiral design. Either way, the teeth taper toward the cone’s apex.

So Which Style of Gearbox is Better?

Either type of bevel gearbox will work when:

- The shafts intersect at odd angles (commonly right angle)

- The shafts are on the same plane

- The shaft has to change rotational direction

However, as always with industrial equipment, what is “best” depends on your specific application and operating environment. Some considerations are functional, while others may be preferential.

Advantages of Spiral Bevel over Straight Bevel in a Gearbox

Spiral bevel gears typically cost more than those with straight teeth, but for many installations, the benefits will-outweigh the cost difference:

- Noise. As the gears rotate, straight teeth impact one another all at once, so they produce a clattering noise that can be significant in medium- and high-speed operations. Spiral teeth mesh gradually as they turn, so operation is significantly quieter.

- Shock loading. The sudden impact of straight teeth coming together while rotating also increases the risk of shock loading, which can cause undue wear or damage and premature replacement.

- Vibration. Spiral teeth are not only quieter, but their smoother operation also produces less vibration making them more efficient.

- Axial thrust. The conical shape of bevel gears causes them to produce axial thrust as they rotate. In spiral bevel gears, the axial force changes depending on the rotational direction due to the curved tooth design.

- Overheating. Straight teeth bevels are in contact more, increasing friction, and the chance for overheating equipment.

- Strength and durability. Because they endure greater initial and ongoing impact, straight teeth are more likely to break. Spiral teeth are concave (or convex, depending on the side you’re looking at). Their curved shape is inherently stronger, and ongoing wear is reduced by gradual, rather than sudden, meshing impact and the fact that several teeth are engaged at any given time.

Spiral bevel gearboxes are ideal for applications such as cooling towers, wind turbines, steel manufacturing, packaging and food processing, material handling, robotics, printing presses, and so on – anywhere that requires any or all of these performance characteristics:

- High speeds

- Speed reduction

- High torque

- Frequent load cycles or continuous operation

Teeth Aren’t the Only Factor in Choosing the Right Gearbox

As useful and versatile as spiral bevel gearboxes can be, some industrial designs call for a different type of gear - helical gears or worm gears.

You’ll need to consider not only gear style but gearbox size, gear ratio, configuration, etc.

All of W.C. Branham’s right-angle gearboxes are also available in stainless steel.

The Right Supplier is as Important as the Right Product

It is critical to find exactly the right gearboxes for your installation because what you choose will affect future productivity and cost-effectiveness. But there are other factors that affect those results, and they all come down to the manufacturer:

- Long-standing reputation for innovation and quality

- Reliable product availability

- Responsive, proactively helpful customer service

- Custom from-scratch design or product modifications

At W.C. Branham, we are proud that our company embodies all of these traits. We introduced the concept of a right-angle hollow-core helical gearbox that is pre-lubricated and leak-proof. But that’s just one example of our dedication to pursuing Solutions in Motion. We are experts on right-angle gears and are always available to work hand in hand with customers to find or build precisely the right product.