It may sound obvious, but industrial equipment that moves also needs to stop. Standard caliper disc brakes that use pneumatic pressure can do the job in many cases, but for certain applications, the spring-applied alternative can be the better choice. One of those applications is emergency braking. While gradual slowing to a full stop often works just fine (though the “gradual” part may be very short), some industrial operations require emergency and/or static holding capabilities, which have to work immediately and without fail. Overhead gantries are a good example. Spring applied brakes are ideal because they can produce higher braking torque than standard pneumatic brakes.

Besides overhead gantries, pneumatic spring applied brakes are well-suited for:

- Robotics

- Rotary indexing equipment

- Wind turbines

- Elevator e-brakes

Spring Applied Brakes Work Differently

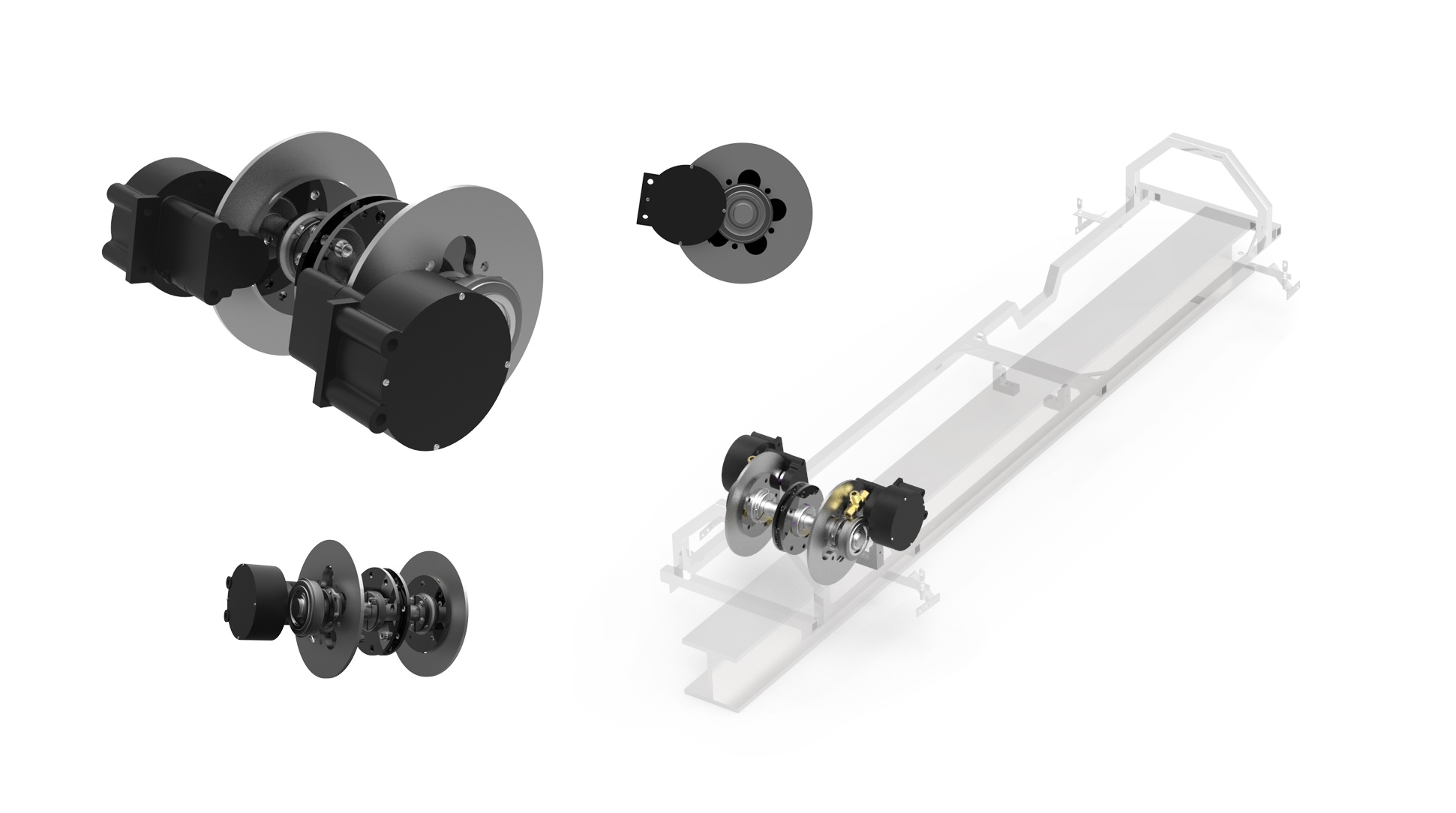

.jpg?width=233&name=pneumatic%20spring%20applied%20brakes%20(1).jpg) Standard caliper disc brakes apply hydraulic or pneumatic pressure to activate the brake piston. When pressure is released, the brake also releases. With spring applied brakes, rather than using the air or hydraulic pressure to create a braking force, springs create the braking force. This means the brakes are always engaged by the springs except when air or hydraulic pressure is applied to “disengage” the calipers, which is the exact opposite of standard brakes.

Standard caliper disc brakes apply hydraulic or pneumatic pressure to activate the brake piston. When pressure is released, the brake also releases. With spring applied brakes, rather than using the air or hydraulic pressure to create a braking force, springs create the braking force. This means the brakes are always engaged by the springs except when air or hydraulic pressure is applied to “disengage” the calipers, which is the exact opposite of standard brakes.

This action makes spring-applied brakes a good choice for applications that require e-stop (emergency stop) action because loss of air or hydraulic pressure will automatically engage the brake. The “redundancy” of power-off-braking-engaged adds safety in applications that involve suspended loads or linear motion.

Benefits of Pneumatic Spring Applied Brakes

The availability of air pressure in a facility makes pneumatic spring applied caliper disc brakes a good option for many companies. Many can be operated on shop air which is typically 90-100 psi, so they can be used in virtually any application, indoors or out. It takes only 85 psi of active air pressure to release the brake piston and store the energy released in the Belleville spring stack. When air pressure is lost, the energy stored in the spring stack is released to engage the disc rotor or rail for positive stopping and holding.

Pneumatic systems are inexpensive compared to electric or hydraulic systems. The operating costs of keeping air pressurized in an enclosed circuit is less than paying for the electricity needed every time an electrical brake engages. Plus they can operate in environments where electricity is not available. Pneumatic systems are also safer. They are simpler and cleaner than hydraulics, so they require less time and money for maintenance. If you need a higher braking force than pneumatics can provide, consider an air over oil intensifier.

Choosing the Right Brake

Adequate torque and power to stop or hold a particular load are critical. When selecting a brake, it is important to properly size the caliper for the application. We recommend using our 20% rule to ensure enough braking force is available in any application.

Although we offer a wide range of spring-applied caliper disc brakes, it can still be difficult to know precisely which style and configuration will be most effective for your application. We’re always here to help answer questions and make recommendations. But we can do more than that.

Over the years, we’ve learned that many of our customers have unique needs best solved with custom modification of an existing product. For spring applied brakes, we can make changes as simple as moving mounting holes to different locations on the brake or creating a custom brake thickness, or we can make complex changes such as designing a much larger (more powerful) brake or designing a brake that releases at less than the standard 60 psi. We are always ready for a new challenge, whether it’s creating solutions in motion or solutions in stopping.