Right-angle gearboxes are known for their durability and low-maintenance design, making them a popular choice across many industries. However, even these reliable components require periodic care to prevent failures and extend service life. From managing alignment issues to selecting the appropriate right-hand or left-hand rotation, proper setup plays a critical role in ensuring efficiency.

If you detect emerging problems quickly, you can avoid costly repairs from untimely, expensive gearbox failures. These problems can also push gearbox components out of spec, weakening performance and causing further damage.

Signs Your Gearbox Might Need Repair

Even though right-angle gearboxes are relatively low-maintenance, you still should monitor them regularly to avoid unexpected downtime. Early detection of problems can prevent major repairs. Below are some of the key signs to watch for:

Overheating

This is the most common industrial gearbox problem. Excessive heat usually stems from high RPM, continuous use, undetected side loads, or a combination of the three.

Signs of overheating can include:

- Heat emanating from the box itself. If that happens, don’t touch it! Spray a bit of water on the housing or shaft to see if it “sizzles” and evaporates.

- Discoloration of the housing.

- Melted plastic components.

- Discolored lubricating grease (or inadequate fluid levels).

Leaks

Damaged seals or gaskets can allow lubricating grease to leak, reducing gearbox efficiency, damaging the bearings, and causing premature gearbox failure. If the shaft seals are broken, water and other contaminants can get inside the gearbox.

Misalignment

Vibration, poor mounting, or wear over time can cause misalignment. Mounting may cause problems if the gearbox is not properly oriented, because it can increase the chances of contamination. Even tiny particulates can damage bearings. Misaligned gears show pitting or wear on one side of the teeth.

Repeated transient thermal expansion can also cause misalignment, as can external heat expansion if the gearbox is located too close to a high heat source.

Noise

Gearboxes naturally produce some noise, but excessive sounds—such as squeaking or rattling—are causes for concern. These noises indicate that gears are out of sync, banging against each other instead of meshing smoothly. You’d need to replace the part immediately.

Unexpected Loads

Right-angle gearboxes are designed for specific load tolerances. Sudden or excessive forces can damage gears or bearings. Bearing blocks are essential for supporting external loads, as internal bearings aren’t meant to manage extra radial or thrust forces, which can shorten service life and reduce efficiency.

Tips to Maximize the Service Life of Your Gearboxes

Preventative Maintenance

Regular inspections and maintenance are essential to maximize uptime and reduce the need for repairs. To keep your gearbox running efficiently:

- Keep the gearbox clean. Prevent dirt, dust, and debris from entering the system and contaminating internal components.

- Maintain proper lubrication. Regularly check and refill lubricants to reduce friction and prevent overheating or gear wear.

- Ensure proper alignment. Misalignment puts extra stress on gears and bearings, leading to premature wear. Routine checks help maintain alignment and extend the gearbox's service life.

Incorporating these practices into your maintenance schedule ensures smoother operations, fewer disruptions, and longer-lasting performance.

Choose the Right Gearbox for Your Application

For industrial equipment, precise performance and reliability are critical. If these requirements aren't met, the equipment will fail when you need it most. To ensure your gearbox stays in top condition, first start by selecting the right configuration for your application.

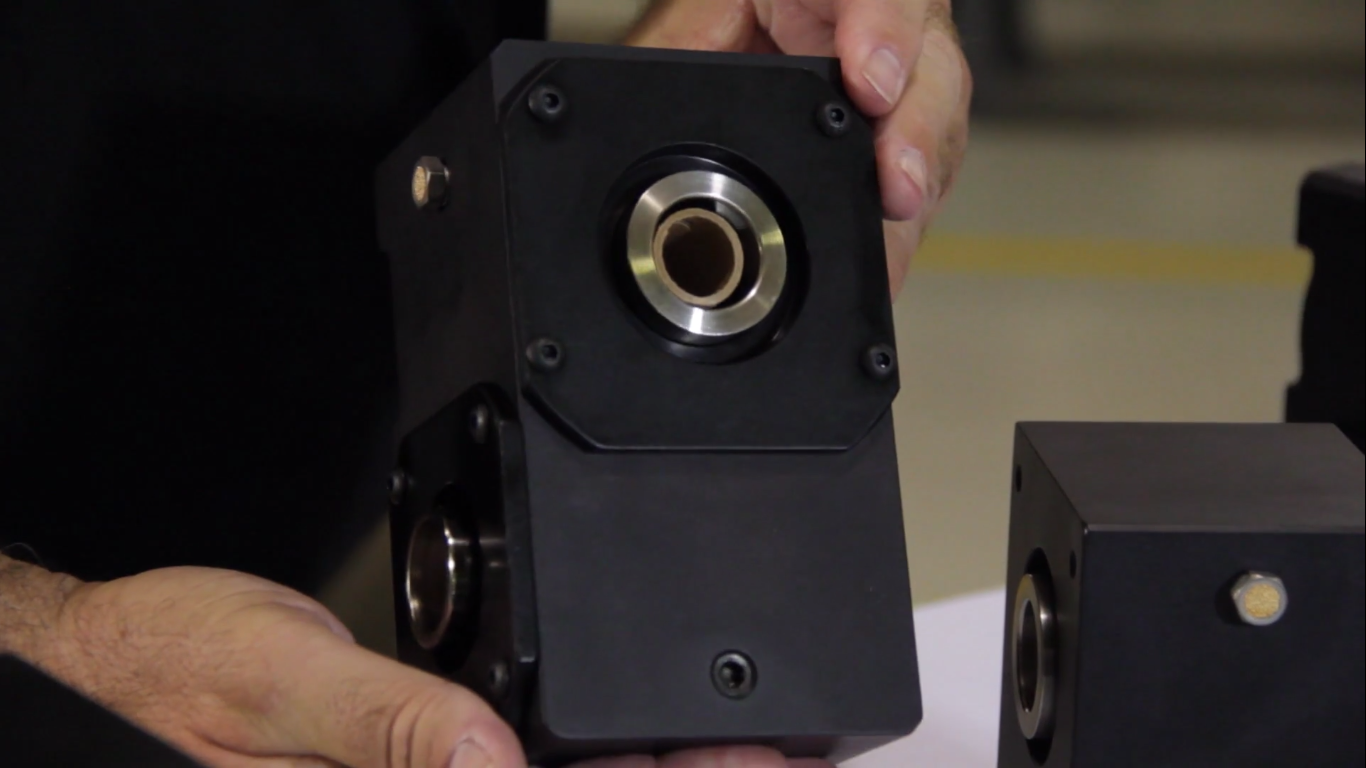

Right-angle gearboxes are used across many industrial applications. W.C. Branham offers several models, including those designed for specialized conditions. The best configuration for your design depends on factors like capability, size, mounting needs, and operating environment.

When selecting a gearbox, determine if it needs right- or left-hand rotation. Proper lubrication is also crucial. The best choice will depend on the gear type, loading, speed, material compatibility, and ambient temperature.

If you find yourself needing to make repairs, consider starting with our DIY repair kits. Otherwise, our experts are always happy to help diagnose and repair or replace our customers’ Branham gearboxes.

Even with proper maintenance, issues can still arise. If your Branham gearbox breaks down despite your best efforts, contact our team.