Right angle gearboxes are used throughout dozens of industries in hundreds of applications that require a reliable transfer of speed or power.

Right angle gearboxes are used throughout dozens of industries in hundreds of applications that require a reliable transfer of speed or power.

They're versatile, but the name can be a bit of a misnomer — the “right” in "right angle" comes from their 90-degree angle — but they can be right- or left-facing.

If your application demands a right angle gearbox, it’s important to know if your design calls for a left-hand or right-hand rotation.

Right-Hand or Left-Hand Rotation

The main differentiation between the right-hand and left-hand versions of right angle gearboxes is the rotation of the gear drives.

For example, a bottom gear in both left- and right-hand rotations turning clockwise would have the top gear turning counterclockwise for left-hand rotation, and clockwise in the right-hand rotation.

With many standard types and sizes are available, and the ability for specialty shaft configurations, ensuring the right angle gearbox for your application is key. Having multiple mounting options also helps simplify your design considerations.

Custom Gearbox Design

Meanwhile, custom designed gearboxes are becoming more common, chiefly because manufacturing to the customer's specifications is easier than ever, due to the newer machine tools as well as design and automation software. Stainless steel, corrosion-resistant gearboxes, for example, are designed to be very rugged and used in wet, hostile, and sterile operating environments.

Where fully custom gearboxes aren’t a feasible option (for example, quantities aren’t high enough), choosing a manufacturer with built-to-order gearboxes from standard modular subcomponents might be a wise choice. Look for manufacturers that employ the latest CAD software, CAM software, and machine tools to streamline post-processing work and reduce one-off costs.

So, when determining the correct right angle gearbox that will work best for your mechanical design, it’s important to identify the key aspects of your design and application.

More Questions to Ask

The following questions will help you select the right gearbox for your particular mechanical application:

- How will the gearbox be used?

- Is it used to adjust something by hand, or a high-speed motor?

- What is the expected duty cycle of the gearbox? Continuous? Intermittent?

- What right angle drive is typically used in the application?

- What mounting features and locations does your configuration require?

- What is your desired input/output configuration?

- What is the required input/output torque? What are the input/output RPMs?

- What is the desired gear ratio of the drive?

- Are you working with a 1:1, 3:2, 2:1, or 10:1 or larger?

- Are there special requirements for the gearbox?

- What temperatures will the box be exposed to?

- Are there special wash-down or corrosion-resistant requirements? The chemicals it’s washed down with will determine if you need special coatings.

- What is the acceptable amount of backlash for your gearbox application? Look to helical, spiral bevel, or worm gear types in aiding your decision.

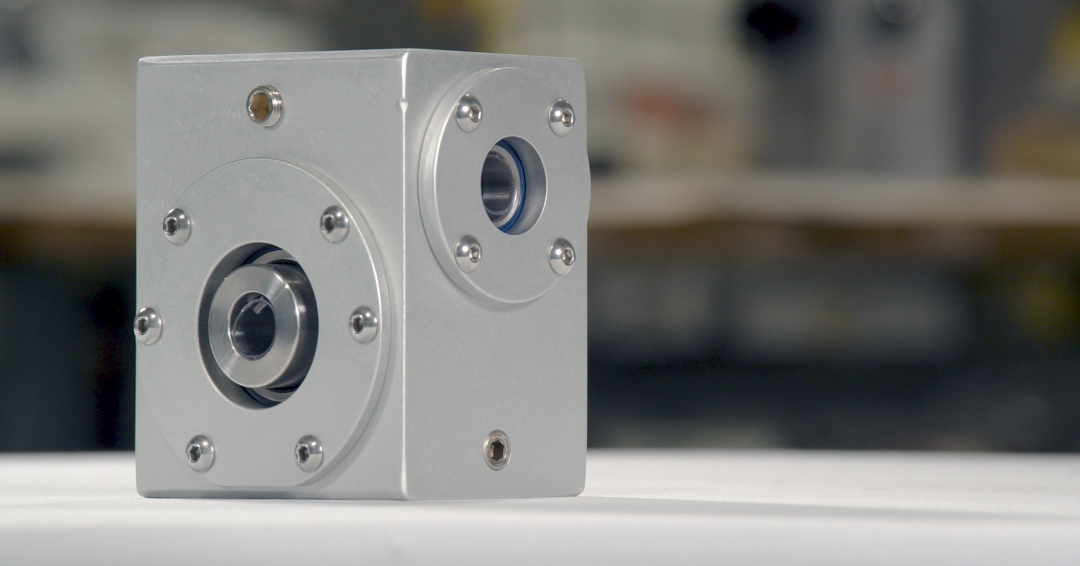

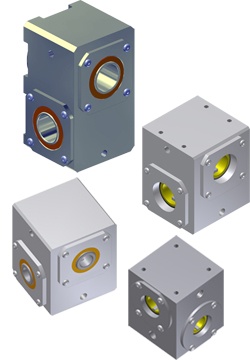

Right angle hollow bore helical gearboxes from W.C. Branham include an all-ball-bearing configuration in a leak-proof sealed gearcase with a pre-lubricated design. They achieve higher thrust and radial loads, have a lower operating temperature for greater efficiency, and longer service life.

Each gearbox has two 45º helical gears that mesh at right angles to rotate power at 90º. They are bi-directional and slide axially along keyed shafts for easy installation.