Magnetic couplers convey force without any actual physical contact. Because magnetic forces attract and repel, they can perform this action in a linear or rotary fashion. But how does magnetic coupling work, and why is it so useful?

Magnetic couplers convey force without any actual physical contact. Because magnetic forces attract and repel, they can perform this action in a linear or rotary fashion. But how does magnetic coupling work, and why is it so useful?

The Magic of Magnets

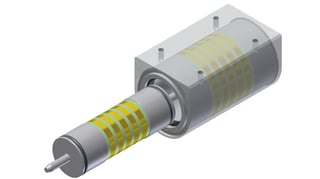

Magnetic coupled cylinders have a carrier that moves from end to end in both directions on a tube.

End caps with pneumatic fittings allow the user to shuttle the carrier from one position to another using air as power in conjunction with a pneumatic control box. It could shuttle a few inches on an industrial machine or move 10 feet on a car wash door (like the DoorTec pictured here on a car wash door).

Powering the Piston

The magnetically coupled cylinder's key feature is the piston enclosed in a tube. Here, this critical moving part is sealed off from the atmosphere outside the tube. While clean and dry on the inside, the atmosphere outside the tube may have a harsh, chemical, corrosive, and even dirty outside world. These influences can be costly by creating wear on critical parts that shorten the cylinder's performance life.

Outside the tube is the carrier (or carriage). It is attached to the piston by magnetic force. Both the piston and the carrier have strong magnets of a special type and configuration to keep them moving together. This is magnetic coupling.

Outside the tube is the carrier (or carriage). It is attached to the piston by magnetic force. Both the piston and the carrier have strong magnets of a special type and configuration to keep them moving together. This is magnetic coupling.

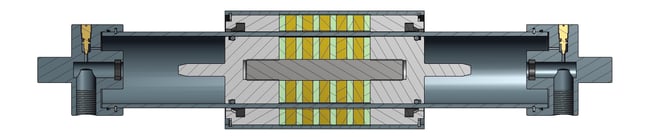

The magnets are rare earth magnets, made up from several alloys. A common base material used in industrial magnets is neodymium. When combined with other ferrous alloys (such as iron, cobalt or nickel) it becomes a rare earth magnet. These magnets are very powerful, especially when used in multiple properly organized sets called an array.

All About the Array

The array consists of a stack of these rare earth magnets separated by spacers in a design to create the optimal magnetic coupling force. The polarity and spacing of the magnets is critical to obtain the force necessary to get the power you require in your magnetically coupled cylinder application. Magnetic arrays in cylinders typically have 3-5 magnets in both the piston and the carrier.

Best Uses for Magnetic Coupling

Industrial applications that might benefit from a magnetic coupled cylinder often operate in wet or harsh environments.

For example, food equipment uses magnetic coupled pneumatic cylinders because they have clean surfaces and are friendly to aggressive washdown requirements. Magnetic coupling is also ideal for car wash equipment or anything else operating with cleaning chemicals and water present.

For more information please contact us. We speak magnetically coupled cylinder!