In many industrial equipment designs, moving parts are mechanically connected to one another. But for some torque-transfer applications, it’s best if the two shafts do not physically meet. This is particularly true in wet, high-pressure, or other harsh working environments. Magnetic coupling provides a valuable alternative because it transfers torque via a magnetic field rather than physical contact.

In many industrial equipment designs, moving parts are mechanically connected to one another. But for some torque-transfer applications, it’s best if the two shafts do not physically meet. This is particularly true in wet, high-pressure, or other harsh working environments. Magnetic coupling provides a valuable alternative because it transfers torque via a magnetic field rather than physical contact.

This type of coupling is typically used for liquid pumps and propeller systems because it keeps the two shafts apart, effectively separating fluid from the motor operating in air. Magnetically-coupled cylinders are ideal for food processing and packaging equipment, thanks to their clean surfaces and their ability to withstand rigorous washdown. In fact, for car washes or other operating systems that are continually exposed to water and caustic chemicals, magnetic coupling offers both reliability and durability.

What’s Different About Magnetic Coupling?

The piston operates inside a sealed tube. The seal protects it from environmental conditions and contaminants including chemicals, corrosives, moisture, dirt and high water pressure. The sealed environment also eliminates the need for lubrication.

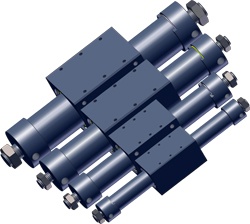

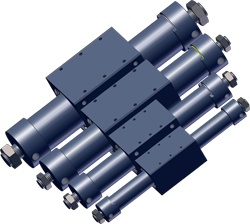

The piston is outfitted with one or more magnets. Outside its tube, there is a carrier mechanism which is also outfitted with magnets. The magnetic configuration provides the force that moves the piston, touch-free.

You can use a pneumatic magnetic coupling to move a load just a few inches or several feet. Magnets can both attract and repel, so you can use these cylinders for either linear or rotary operation.

Not Just Any Magnets

The magnets we use in our cylinders are rare earth magnets made from a special alloy that combines neodymium as a base with a ferrous metal such as iron, nickel or cobalt. They are more powerful than everyday magnets, especially when used in multiples.

When it Comes to Pneumatic Cylinders, We Have You Covered

W.C. Branham manufactures a wide variety of rodless actuators including magnetically-coupled cylinders. We never create just one version of any product. After all, we know there’s at least one element of every industrial equipment design that makes it unique — more often, multiple elements. By giving you a variety of styles and configuration options, we make it easier to get the right fit. And if your needs are truly unusual, we do custom design, too. Just give our team of experts a call.