7 Factors in Choosing the Right Gear Drive Lubrication

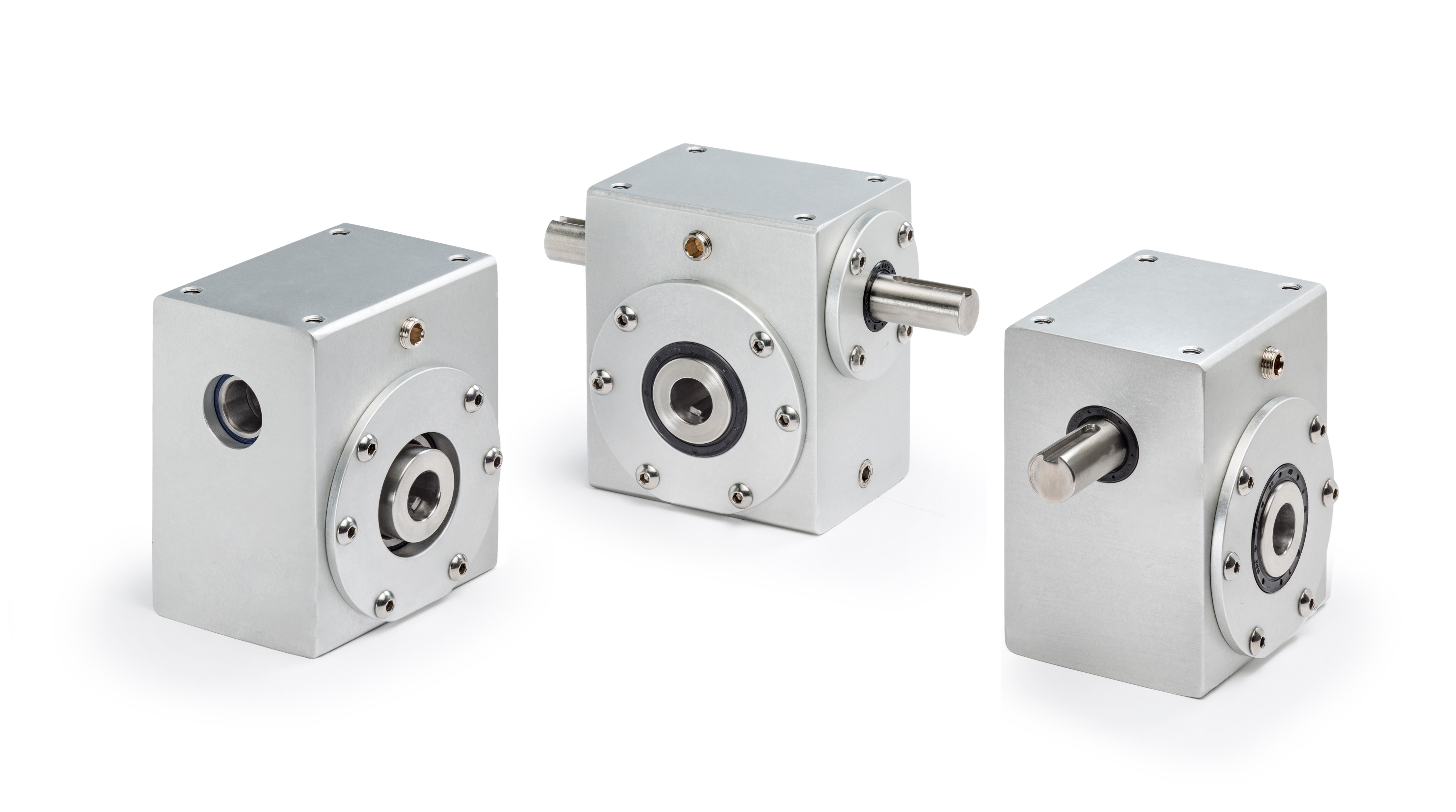

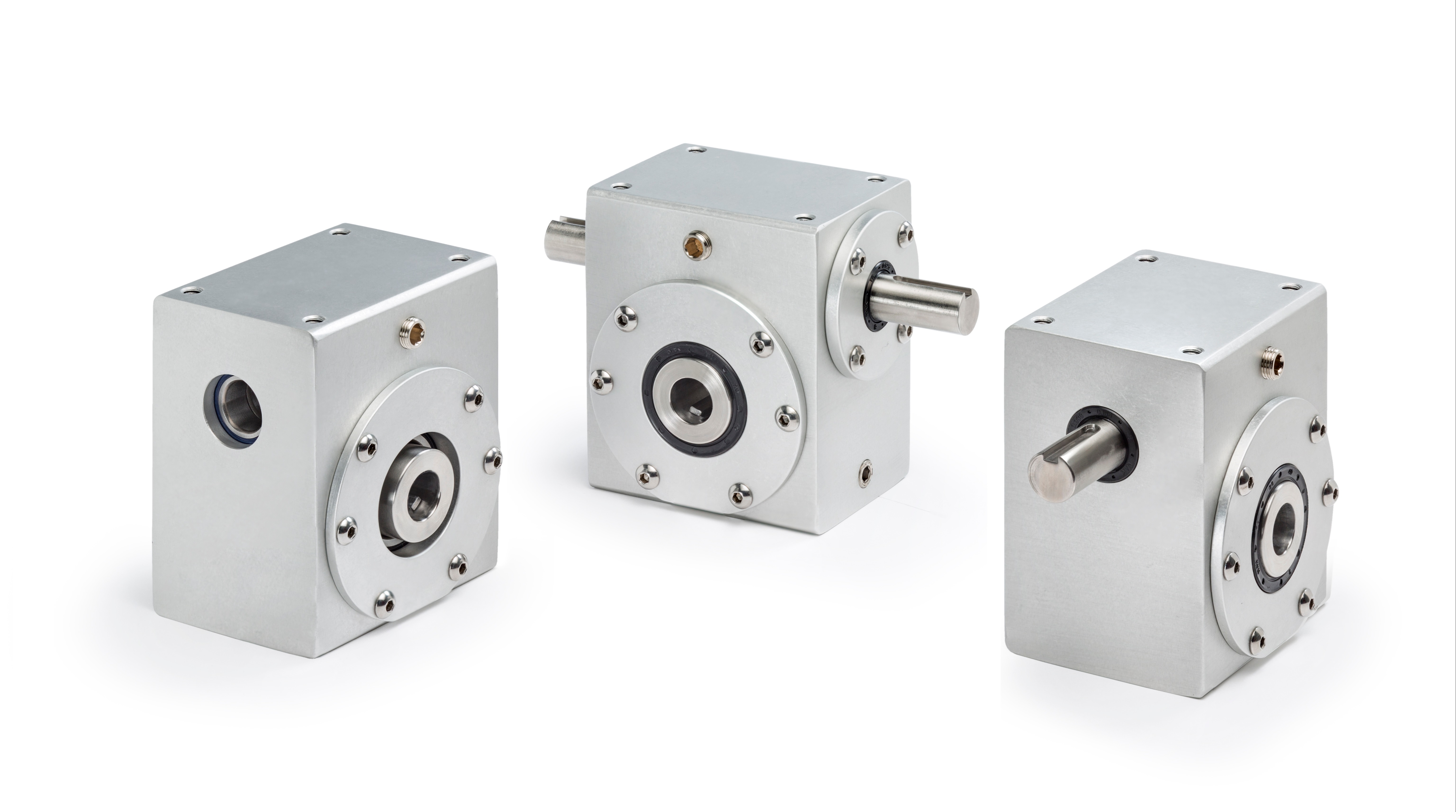

Every part in a complex machine presents a chance for failure, especially if they're not designed or maintained properly. Sometimes the simplest parts get overlooked. A right angle gearbox doesn’t require as much attention as other more complex parts, but it still can bind, grind, or fail without proper lubrication.

No matter what your application, it's absolutely essential to maintain your right angle gearbox with the proper lubricant. Here are seven common factors that can affect which right angle gear drive lubrication options you should choose, as well as tips on proper installation and maintenance.

Resource: Right Angle Gearbox FAQs [VIDEO]

1. Open vs. Closed Gears

Your gear drive lubrication options will change depending on whether you're working with open or closed gears.

- Open gears are installed in an open environment without being enclosed or, in some cases, enclosed but not sealed. The lubricant used in open gears must be sufficiently tacky–like a thicker, grade 2 type grease–to adhere to the gear teeth and offer a boundary layer of lubrication for a sufficient period of time. Lubrication of open gears should be applied frequently and must be applied directly to the gear teeth.

- Closed gears are enclosed in a sealed gearcase. This allows the use of low-viscosity lubricants like lightweight greases and gear oils, which constantly provide lubrication to the gears. When maintaining a closed gearcase, it is important to completely drain the old lubricant from the gearcase and install new lubricant of the proper type and volume per the manufacturer's recommendations.

While less maintenance is required for closed gears, it's still important to install the correct volume of lubricant into the gearcase: too little lubricant may not adequately contact and lubricate the gear teeth; too much lubricant will not allow for proper heat dissipation and may create excess pressure within the gearcase, causing leaks around the seals.

2. Gearing Type

The type of gears in your right angle gearbox will dictate the internal speed of your gearbox. Accordingly, each type of gear–worm, bevel, helical, and planetary–requires a different type of lubricant in order to perform properly. The manufacturer will usually recommend the proper lubrication for the type of gear in the right angle gearbox for normal loads.

For example, spur and bevel gears use a low speed and low slide lubricant, while helical or spiral bevel gears use medium slide and medium speed. Worm gears always operate with high or excessive sliding, with very high loads.

3. Load

If you are running your right angle gearbox with high loads, you will need a high-performance lubricant. It is important to have a high-pressure industrial oil, preferably synthetic, in order to maintain viscosity and proper lubrication. High loads create high temperatures, so a high flash point is essential for safety as well as proper wear in high-load applications.

4. Gear Speed

Higher speed operations require low viscosity lubricants. If you are operating your right angle gearbox at consistently higher speeds, an oil that is too thick will increase drag and temperature, creating a potentially dangerous situation. Low viscosity lubricants are recommended for all applications with right angle gear drives that operate at very high speeds.

5. Materials Compatibility

Particularly in the case of high-pressure applications, it is critical to be sure that the additives in the lubricant are not corrosive to the gears. This is particularly true for bronze gears, but some high-temperature lubricant additives can even corrode unhardened steel. It is vital that you check to make sure you have proper compatibility before lubricating your right angle gearbox.

6. Ambient Temperature

If the application is outdoors, you may have to adjust the viscosity to match the conditions. Cold climates require a lower viscosity oil for proper lubrication to avoid excessive internal loss and wear. Hot climates require a thinner oil, which will not build up heat.

7. Lubricant Grade

When it comes to gear use, selecting the appropriate lubricant for your gear drive is critical to ensure optimal performance and longevity. This is especially true in industries where equipment is involved in the production and processing of food. In these cases, food grade lubricants are a must to ensure the safety of the product being produced and consumed. It's important to pay close attention to the lubrication grade being used as certain additives and contaminants can have harmful effects on food. Using the right type of lubrication can not only keep your equipment running smoothly, but also ensure the safety and quality of your end product.

Conclusion

For every type, speed, and application, be sure to always drain out the old oil completely when the right angle gearbox is warm, and do not use solvents to finish the job. Check the old oil for signs of discoloration or burning, which may be a sign you need to consider a different lubricant.

A regular maintenance and lubrication schedule can save your equipment from critical breakdowns and keep your right angle gearbox running for many years with regular operation.