Right-angle gearboxes are vital components in industrial machinery, providing a compact and efficient solution for transferring rotational power at a 90-degree angle, making them an essential piece in many industries.

But what makes right-angle gearboxes so versatile? This post will explore the different types of right-angle gearboxes and examine the factors to consider when selecting the right one for your specific applications. By understanding these nuances, you’ll be better equipped to make informed decisions for your equipment.

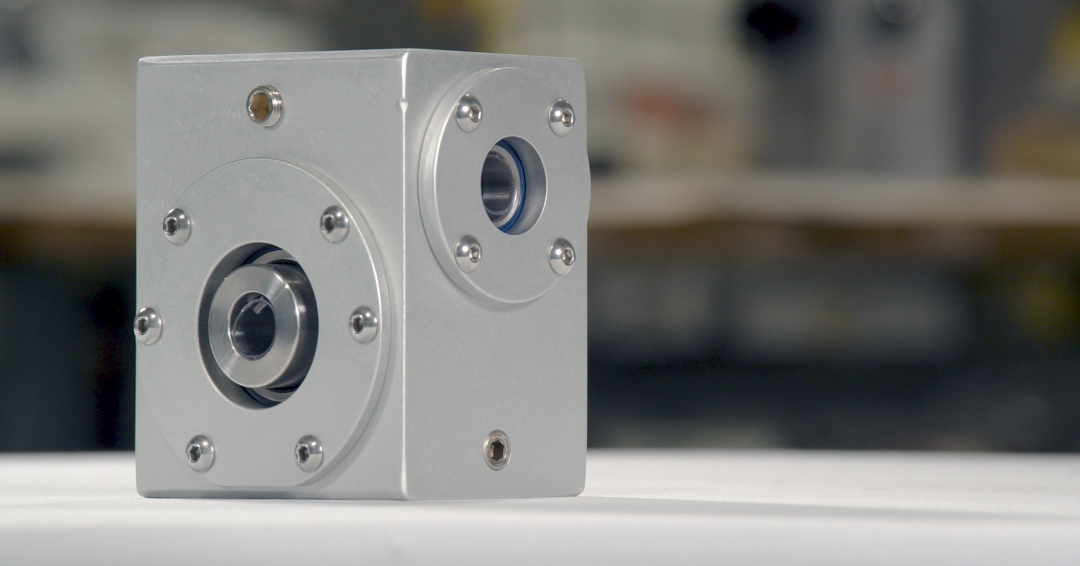

Different Types of Right Angle Gearboxes

A right-angle gearbox is designed with the driveshaft and output shaft positioned at a 90-degree angle, using rotational motion to transfer power efficiently. You’ll find these gearboxes in a wide range of mechanical setups—for example, automotive transmissions and many other industrial machinery applications.

There are several types of right-angle gearboxes, each suited for different applications. Here are the most common ones:

Worm Gears

A worm gear drive consists of a screw (the worm) that meshes with a gear or wheel. This design enables control over rotational direction, speed, and higher torque transmission. There are many sub-varieties of worm gears, including single-throated, non-throated, and double-throated.

Worm gears used in industrial applications can be one-directional, making them valuable for regulating speed, braking, and holding. Good examples are elevators and other lifting mechanisms. For these applications, a worm drive is not used alone, but as a secondary braking system.

Bevel Gearboxes

Bevel gearboxes produce greater thrust and radial loads, operate at lower temperatures, and last longer due to their high efficiency. They run smoothly, quietly, and are ideal for applications like packaging, cutting, and labeling.

Bevel gearboxes have many advantages:

- They’re on-plane, meaning they provide direct power transfer at a right angle.

- They’re precise with less than half of a degree of backlash.

- Their power can be transmitted left, right, or in both directions with the same shafts, making them the perfect candidate for a three-way coupling.

- Precision engineering leaves minimal wear on gears.

Helical Gearboxes

The gears in a helical right-angle gearbox are cut so the teeth curve with the cylinder shape of the gear in the same way a helix is formed. This allows the teeth to engage more gradually and stay in contact longer as two gears rotate. The result is a gear-pairing that is bi-directional and capable of higher thrust and lower operating temperatures. The direction of the cut determines the output rotation of the gearbox. Bores in a helical gearbox are offset by twice (2x) the radius of the gears.

Check out our MICROGEAR® Product Brochure

Key Considerations for Gearbox Selection and Design

Selecting the right gearbox requires careful consideration of various factors to ensure optimal performance and longevity.

- First, determine how the gearbox will be used. Is it for manual adjustment or driven by a high-speed motor? Is the duty cycle continuous or intermittent?

- Next, evaluate your specific application needs, such as input/output torque, RPMs, and the desired gear ratio, whether it’s a 1:1, 3:2, or something larger like 10:1. Consider load support for overhung, axial, or external moment loads to avoid misalignment.

- Proper sizing is essential. Our right-angle gearboxes range from 2.87 to 6.6 inches tall, but we also have custom designs to meet exact size requirements.

- Gear orientation is another critical factor. Determine whether you need shaft or hollow-core configurations and whether they will protrude horizontally or vertically.

- Think about mounting features and locations for your setup, and whether you need a helical, spiral bevel, or worm gear to minimize backlash.

- Environmental factors also play a significant role. Gearboxes exposed to extreme temperatures, shock, vibration, or those requiring wash-down or corrosion-resistant materials, may need special coatings or stainless-steel components.

By carefully considering these factors, you can ensure your gearbox will deliver the precise performance needed for your application.

Learn more about the specific gearboxes we have to offer at W.C. Branham in our Right Angle Gearbox Brochure.