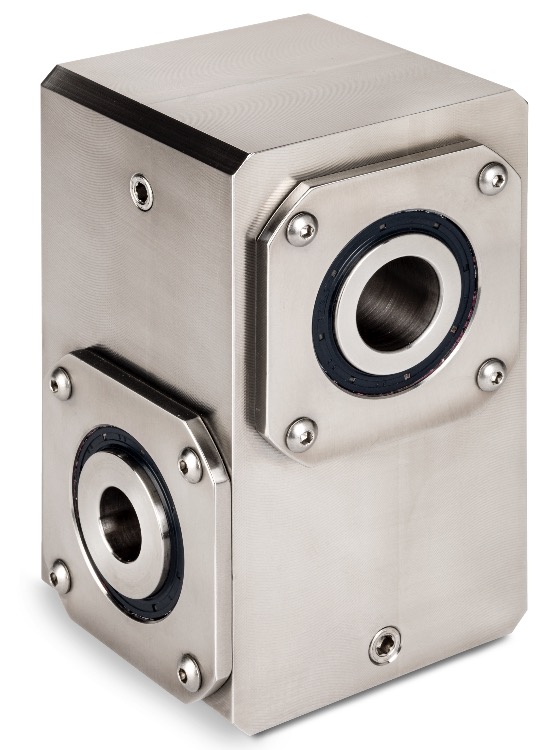

Nothing looks more professional than stainless steel gearboxes. They’re so shiny and clean-looking. And that might actually matter if your working environment sees visiting guests or official inspectors. Other equipment that needs re-painting or a new powder coating can make the entire facility seem sub-standard.

Nothing looks more professional than stainless steel gearboxes. They’re so shiny and clean-looking. And that might actually matter if your working environment sees visiting guests or official inspectors. Other equipment that needs re-painting or a new powder coating can make the entire facility seem sub-standard.

But a pretty face isn’t enough, especially in certain industrial applications. You need gearboxes that can perform reliably as spec’d, for a long time, with minimal fuss, so there are serious functional reasons to choose stainless steel gearboxes.

It All Comes Down to Corrosion Resistance

Stainless steel is a necessity in sanitary and washdown environments that require the utmost in both product protection and gearbox performance. It is uniquely weather-proof, water-proof, and longer-lasting. It costs more on the front-end but creates fewer headaches on the job.

Maintaining a sterile environment is critical to avoid contamination. Both the products being processed and the industrial equipment itself must be protected from contaminants. A sealed gearbox keeps lubricant in and potential contaminants out. That eliminates infiltration of moisture or fine particles such as dust from corn milling.

But the gearbox also has to withstand repeated spray, steam, and pressure from washdown operations. Stainless steel has smooth surfaces that won’t trap moisture, particles, or bacteria. It is highly resistant to both acid and alkaline solutions including chlorine. And its durability is unsurpassed, enabling it to withstand extreme washdown water temperatures and pressure. Because it is virtually maintenance-free, it is a cost-effective choice over the life of the product, too.

Stainless steel won’t rust. It resists corrosion. There is no paint to chip off. Traditional cast iron and epoxy-painted gearboxes do not hold up under the harsh conditions that expose equipment to water, acids, oils, harsh chemicals, abrasion, and high-pressure washing down.

Where Do Stainless Steel Gearboxes Really Shine?

So, you may be wondering, what are the best applications for stainless steel gearboxes?

- Food processing

- Beverage bottling

- Meat packing

- Pharmaceutical or medical device manufacturing

- Chemical processing

- Packaging equipment

- Marine industries. We’ve done applications on boats and ships and parts for oil rigs. Anytime you get into an off-shore environment, you’re dealing with salt water, which is very corrosive. Most other materials simply don’t last.

- Any wash down application

Some operations require that gearboxes be lubricated with H1 or H2 food-grade grease. With stainless steel gearboxes, that doesn’t limit your design options.

We Have You Covered

Here at W.C. Branham, we make a broad selection of stainless steel right angle gearboxes.

They are available in multiple configurations with a variety of bore sizes and many more bore center distance options including one-inch center distance, ideal for either continuous duty or high cycle applications. All of them accommodate food-grade lubricant if needed.

Our stainless steel gearboxes are entirely constructed from stainless steel, so you have the maximum performance when it comes time. Many competitors have an electro-nickel plated housing with some stainless internal components, but that’s not a true all-purpose washdown box. It might be corrosion resistant to a point and it may be fine for your application, but an all-stainless box is fool-proof. If an all-stainless gearbox is cost prohibitive for your needs on the front end, we have you covered with our CRL washdown gearboxes as they are also sealed and leak-proof to operate safely and reliably in wet, hostile, or sterile environments.

an all-stainless box is fool-proof. If an all-stainless gearbox is cost prohibitive for your needs on the front end, we have you covered with our CRL washdown gearboxes as they are also sealed and leak-proof to operate safely and reliably in wet, hostile, or sterile environments.

Unusual Specs? Give Us a Call

Simply adding food-grade grease to any gearbox cannot achieve the performance and protection levels required for certain applications. It takes the right gear design, superior materials and workmanship, plus the food-grade lubricant to ensure safe, cost-effective operations. This is why W.C. Branham offers so many choices.

Nonetheless, we know your application may require custom design. That’s one of our specialties. We always welcome the opportunity to discuss your project whether you’re looking for design ideas or simply need us to point you toward the right product. We are also happy to provide 3D STEP CAD files for any of our gearboxes.