Mechanical engineers design and build things that work. Tools. Machines. Entire systems such as automated industrial machinery. Many of these mechanical engineering projects are highly complex. And every one of them is different. Yet, choosing the best design and components for each project follows a similar path.

Mechanical engineers design and build things that work. Tools. Machines. Entire systems such as automated industrial machinery. Many of these mechanical engineering projects are highly complex. And every one of them is different. Yet, choosing the best design and components for each project follows a similar path.

We all solve problems every day. But when it comes to mechanical engineering projects, solutions have to be precise. If every project detail isn’t well-thought-out, the result won’t work. At least not well. So there is a prescribed decision-making process for mechanical engineering projects. Following these steps sequentially ensures your project will produce the best possible solution.

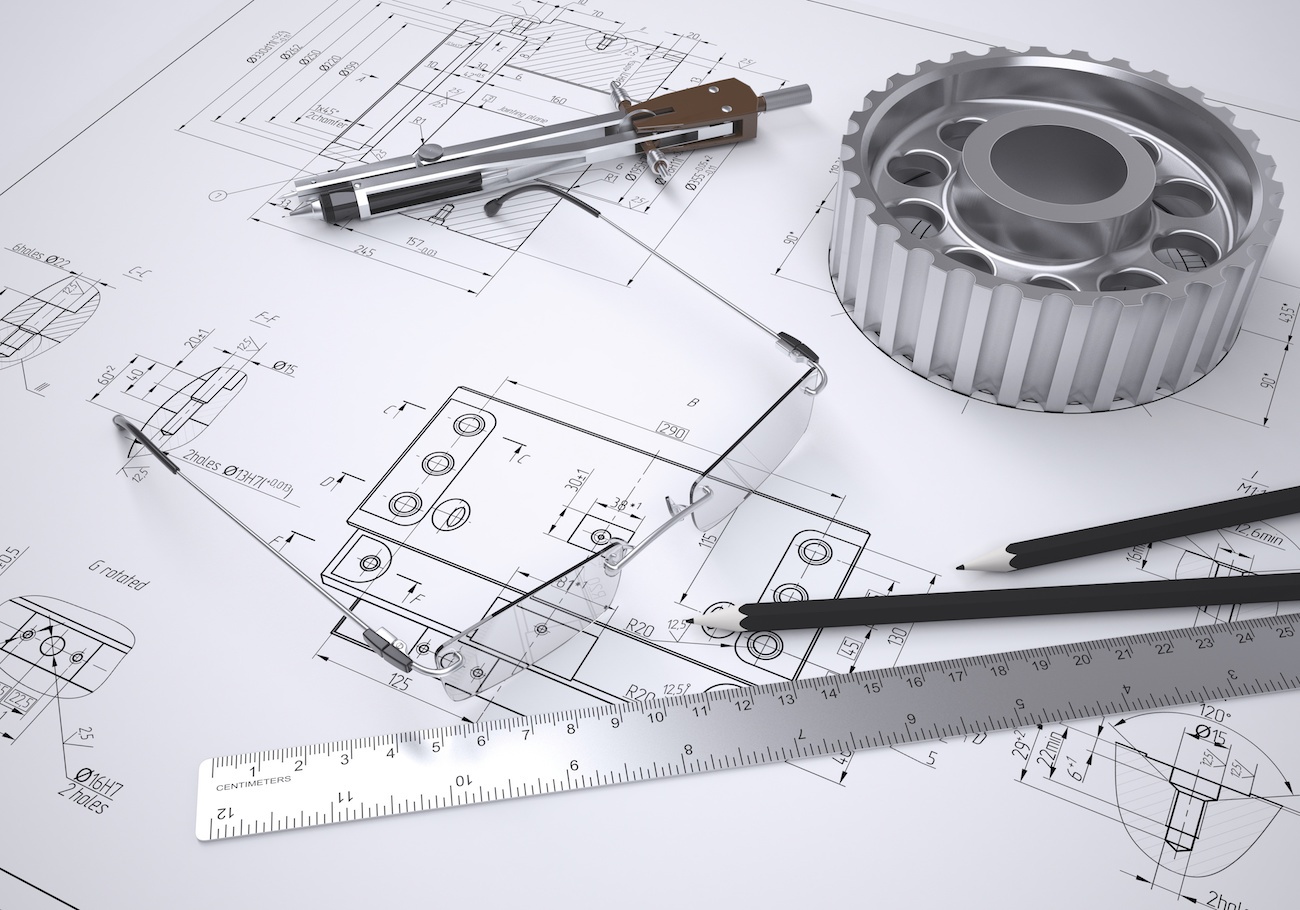

Here are the essential tools you need to start mechanical engineering projects:

1. Identify your goal

You can’t find a solution until you understand the problem. What is the purpose of this mechanical engineering project? Clearly defining the goal ensures you won’t inadvertently focus on a partial solution or fail to consider all your options.

2. Research the project

- Who will use the engineered solution, and how?

- What kind of environment will it function in – atmospheric conditions, presence of people, physical and spatial considerations?

- What are the must-have design requirements?

- What constraints exist – physical or budgetary limitations or functional issues that will (or might) affect the ultimate design?

3. Brainstorm possible solutions

It’s important to understand all your needs and constraints before you start to envision solutions. Otherwise, you might overlook possibilities or focus on ideas that won’t fully achieve your goal.

4. Planning

With your possible solutions in mind, identify:

- Key design criteria.

- Materials that will be needed.

- If there are pre-existing manufactured parts you can incorporate or adapt to meet your specific needs.

It’s not unusual to use manufactured parts in your design, but it’s essential to choose the right products. Many products, such as gear drives, caliper disc brakes, and pneumatic cylinders come in multiple models with multiple customization options. Wide selection ensures you can spec exactly the right product, but identifying that product can feel overwhelming. And you don’t want to make a mistake.

Talk to prospective suppliers about your application. If you give them as much detailed information as you can, they can give you the best recommendations. Taking advantage of their product knowledge and experience will save you time and frustration, and help you avoid costly mistakes. They may even suggest design or component alternatives you hadn’t considered, based on your particular constraints. The more solution alternatives a given manufacturer offers, the more likely you are to find products that match your requirements in terms of function, construction, availability, and cost.

5. Identify the most promising solution

Now it’s time to pull it all together. You know what you need to accomplish. You’ve identified some solutions that could work. You know what custom products are already available to build out your design. Apply what you know to each of your ideas, to find the best one.

Using these essential decision-making tools will help you get all your mechanical engineering projects off to the best possible start.