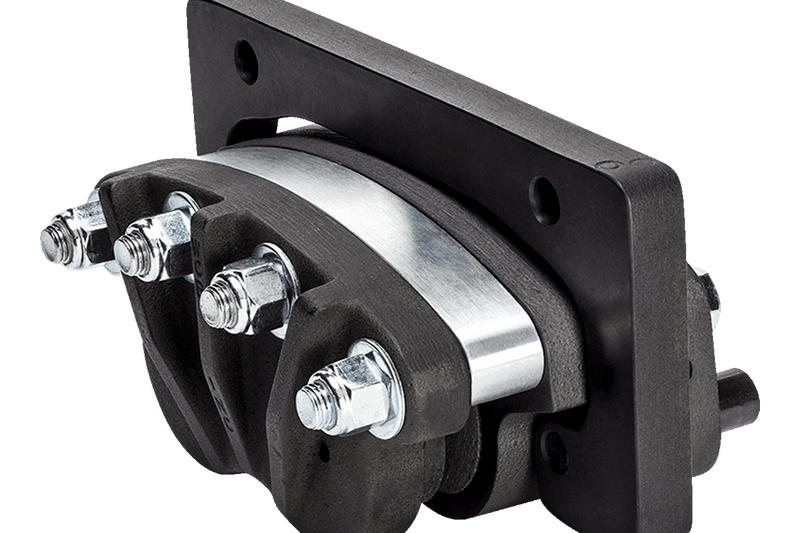

Pneumatic caliper brakes are a popular choice to slow or stop equipment or maintain tension in manufacturing and other industrial processes. Because braking action is critical to both efficient production and safety, it is essential to know what to watch out for to ensure your caliper brakes are functioning properly.

Caliper disc brake performance starts with correct installation. It continues with regular inspection that allows you to catch wear or other issues early. That way, you can adjust or replace as needed to maintain consistent operation, extend brake life, and prevent catastrophic (and costly) failure.

What should you watch for with pneumatic brakes? Any of these common caliper disc brake issues could trip you up if you aren’t regularly paying attention.

Proper Mounting Orientation

Mounting orientation can affect the brake’s ability to function properly, potentially interfering with performance as well as causing damage. Pads should be mounted parallel to the disc so they will not wear unevenly.

Leaks and Corrosion

These are two of the most common maintenance issues.

Pad Wear

Pads apply pressure to the disc to slow and stop rotation, so the pad must be thick enough to handle that without damaging the disc. Watch for uneven or excessive wear, and replace pads before they can cause problems. But note that excessive wear may also indicate your brake is undersized. This guide will help you select the best size of pneumatic brake for your application, or you can simply use this handy downloadable calculator to find our recommended size.

Proper Retraction

If you’re using retractable brakes, make sure the spring is retracting fully from the disc. Corrosion or built-up debris could interfere with this braking action. In addition, the small retractor springs have a finite cycle life. Periodic checks can be made to determine if the brake needs to be refurbished or even replaced.

Loose Fittings

Repeated component movement, vibration, etc. can cause fittings to loosen over time. As part of regular inspection, check to be sure bolts are tightened and screws that hold the pads are not loose.

Reluctant Guide Pins

Single-sided, or floating, caliper disc brakes have a piston and brake pad only on the inside. On the outside, the caliper slides on pins to compress the brake. If debris accumulates on the pins or brackets, it can interfere with smooth caliper operation, effectively leaving the brake out of kilter, with only one functioning pad.

Questions? We’re Here to Help!

As noted earlier, choosing the proper size of pneumatic caliper brake is fundamental to ensuring reliable, long-term performance. Our Branham team is happy to answer questions, help you make the most effective choice, and also advise you about inspection and maintenance details that will help keep your caliper brakes functioning smoothly and safely. Just give us a call or drop us an email.