Rodless air cylinders save valuable machine space because they are almost half the overall length of a comparable rod cylinder while producing the same, if not more, punch. And the ability to add an external guide can make them even more versatile.

Rodless air cylinders save valuable machine space because they are almost half the overall length of a comparable rod cylinder while producing the same, if not more, punch. And the ability to add an external guide can make them even more versatile.

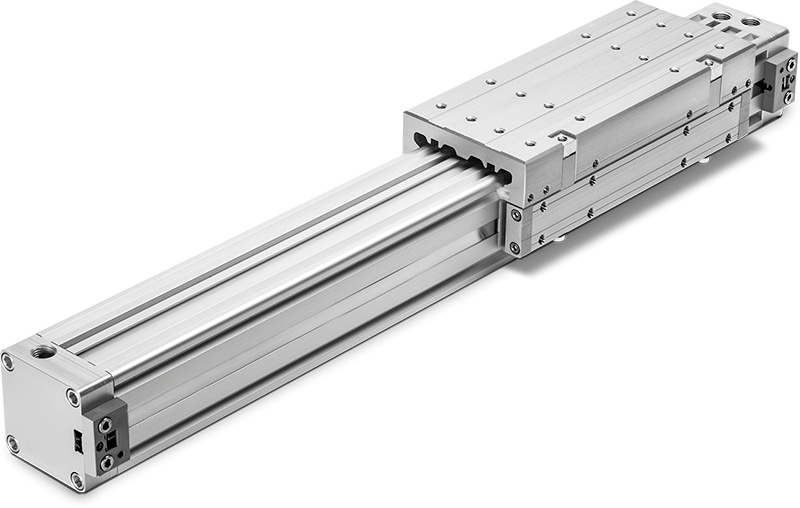

The external guide makes it possible to load the slide with lateral forces and torques. Tools or other drives can be mounted directly on the slide. In the case of our DURATRK™ line of rodless air cylinders, the adjustable slide guide is capable of handling high moment and forces in all directions. With screws provided, installation can be handled with the following steps and a few easy adjustments.

Here's how to install an external guide on a rodless air cylinder.

- Place the carriage onto the body. Cut outs of the carriage should adjoin the yoke of the cylinder.

- Insert the guide strips into the channel of the carriage and "V" groove of the body of the cylinder.

- Slide the other guide strip into place. The carriage should be level and slightly raised above the cylinder body.

- Apply Loctite® 222 to the threads of the grub screws on both sides of the carriage.

- Screw in two dog point grub screws on either side of the carriage at one end until a small amount of resistance is felt.

- From the other end of the carriage, insert two wire strips into the channel in the guide strip until they hit the grub screws at the opposite end. Tighten.

- Screw in the remainder of the grub screws until a small amount of resistance is felt.

- Adjust screws until the carriage moves freely, but with no lateral movement.

- Align the yoke with the carriage. Assemble the clamp wedge and cone nut together and fit to the carriage.

- Put washers into screws and apply adhesive. Push in clamp block and cone nut, leaving a gap between the side carriage and the yoke of the cylinder. Tighten screws.

DURATRK™ rodless cylinders cover a wide variety of applications.

A precision linear guideway and recirculating ball bearing system is added to both the DTFL and DTKFL (short) style rodless cylinders. It is our most robust, heavy-duty, models available. The guideway is located 180º from seal slot to reduce loading on the piston/yoke. Save engineering time and money by integrating the guiding mechanism with the main cylinder.