Worm gears can be found in everything from acoustic guitar tuning pegs to heavy machinery. Here at W.C. Branham, we specialize in manufacturing worm gears for industrial applications. Typically, these are applications where space is a concern, such as packaging equipment, small machinery, and conveyors.

Worm gears can be found in everything from acoustic guitar tuning pegs to heavy machinery. Here at W.C. Branham, we specialize in manufacturing worm gears for industrial applications. Typically, these are applications where space is a concern, such as packaging equipment, small machinery, and conveyors.

Worm gears conserve space

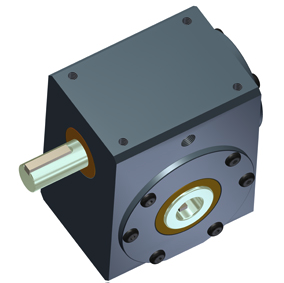

A worm gear uses a spiral-threaded shaft—called a worm but essentially a screw—to drive a wheel-shaped gear with teeth. The screw and wheel meet at a 90o angle to form a right angle gearbox. Despite its simplicity, the worm gear can efficiently manage both power and torque in industrial applications. The compact design allows you to use fewer gear sets to achieve high gear ratios, with significant speed reduction and torque increase.

W.C. Branham is an industry leader in manufacturing right angle gearboxes. We offer three model configurations with multiple options. 3D CAD files are available for all of them.

Worm gears help regulate speed, too

The right angle worm gear is the most commonly used gear for reducing speed in industrial applications. It is durable, versatile, tolerant of shock loads and overloading, and cost-effective. Worm gears operate smoothly, minimizing noise—an important factor in many industrial settings. And because worm gears have fewer moving parts, there is less risk of failure.

Worm gears can be used as secondary braking devices because they only turn in one direction. They cannot work in reverse. For example, elevators and lifts often use worm gears to regulate load speed and prevent free-fall. Conveyor systems that use worm gears will lock up when not being used rather than running backward. In applications where two-directional movement is required, two worm gears are used—one to manage each direction.

Speed reduction ratio is determined by the number of threads in the worm shaft and the number of teeth in the gear. You can couple two gear reducers to increase speed reduction.

Worm gears are ideal for low to moderate horsepower applications, where you need compact size but high ratios and high output torque. Is a worm gear the best choice for your particular design or installation? Or are you not sure which of our right angle gearboxes to use? We can help you decide—just contact us to get started.