Reliability is crucial for any industrial equipment, but most of all when machinery is operating under high-speed, high-torque conditions. For these applications, a high-speed right angle gearbox is often the best design choice to ensure cost-effective, long-lasting, safe performance. Right angle gearboxes are also compact, an important advantage when space limitations are a design factor.

Reliability is crucial for any industrial equipment, but most of all when machinery is operating under high-speed, high-torque conditions. For these applications, a high-speed right angle gearbox is often the best design choice to ensure cost-effective, long-lasting, safe performance. Right angle gearboxes are also compact, an important advantage when space limitations are a design factor.

High-speed automation is common in applications such as packaging, bottling lines and other food processing operations, pulp and paper manufacturing, heavy manufacturing such as cement or steel, and mining. And locations such as car washes, food and beverage operations, or medical facilities typically use high-speed roll-up doors.

Which High-Speed Right Angle Gearbox is Best for Your Application?

The gearbox you choose will affect operational efficiency, reliability, overall performance, and long-term cost. The specific components and how they are configured will affect speed, torque, noise, maintenance requirements, and the ultimate size of the gearbox. W.C. Braham manufactures a wide range of helical, worm gear, and spiral bevel gearboxes. (You can read about each of them in detail here.)

Before you make any design decisions, you’ll need to ask yourself a lot of questions. For example, what are your horsepower and input speed requirements? And what about target output speed or torque? It’s best to start at the beginning: how the gearbox will be used. That will help you consider vital details such as:

- Output speed required, as well as the input speed

- The desired gear ratio (1:1, 2:1, 3:2, etc.)

- Duty cycle frequency including starts and stops required

- Environmental characteristics (washdown, caustic chemicals, and extreme temperatures can affect gearbox performance and life)

For some types of applications, you will also want to specify the acceptable amount of backlash (space between two meshing gears). This assures optimal lubrication, so the gears won’t lock up.

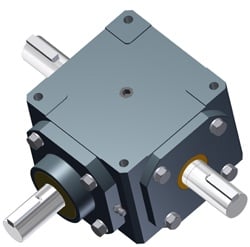

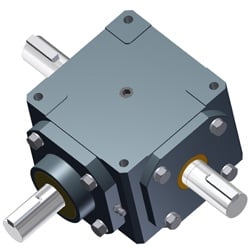

You’ll Probably Want a Spiral Bevel Style

Despite their small size, spiral bevel gearboxes can handle high torque and high speeds thanks to their curved teeth. The teeth meet at a 90o angle, but their curved shape improves traction and flexibility and allows for better, more consistent lubrication. The result is smooth, quiet, enduring operation with little risk of overheating.

W.C. Branham makes hollow bore spiral bevel gearboxes and also two-way, three-way, and all-way models. We also make units that offer Continuous Recirculating Lubricant for continuous duty and high cycle applications, and stainless steel gearboxes for wet, corrosive, or otherwise hostile environments.

Although you can spec multiple configurations using our standard options, custom design may still be your most effective solution. Especially under high-speed, high-torque conditions, you need gearboxes that precisely match your specifications. A unit that is “pretty good” won’t be good at all in the long run.

No worries, though, our engineering and design pros are always looking for another good challenge. So, whether you’re sure you need custom design, or you’re stumped on a spec’ing detail, give us a call.