Actuators play a crucial role in various industries, enabling the smooth and efficient movement of machinery components. Among these, double-acting cylinders stand out for their ability to provide control in both forward and backward movements. There are also differences when it comes to hydraulic and pneumatic powering of cylinders. Let’s start by exploring the real-world applications, design options, and control considerations of double-acting cylinders.

Applications of Double-Acting Cylinders

Double-acting cylinders find applications across diverse industries, from manufacturing to space exploration. Here are some real-world scenarios where these cylinders demonstrate their efficiency:

- Knifing in Paper-Making: Double-acting cylinders smoothly cut paper rolls on the fly, ensuring precision and speed.

- Door Manufacturing: Used to assemble and glue panels, double-acting cylinders provide uniform pressure and controlled retraction.

- Warehouse Conveyors: Arm-mounted cylinders efficiently handle items on conveyor belts, ensuring seamless operations.

- Cage Washer: Sprayer-equipped cylinders facilitate thorough washing cycles in cage cleaning processes.

- Hot Furnace Safety: Double-acting cylinders open furnace doors when necessary, prioritizing safety in extreme temperature environments.

- Silk-Screening: Ensuring even ink coverage, double-acting cylinders power the sweeping motion of the silk-screening process.

- Powder-Coating: Essential for uniform painting, these cylinders operate sprayer equipment both vertically and horizontally.

- Beyond industrial machinery, double-acting cylinders are found in elevators, forklifts, car transport carriers, log-splitters, and even in funhouses or haunted houses to animate mannequins.

Configuration Options for Double-Acting Actuators

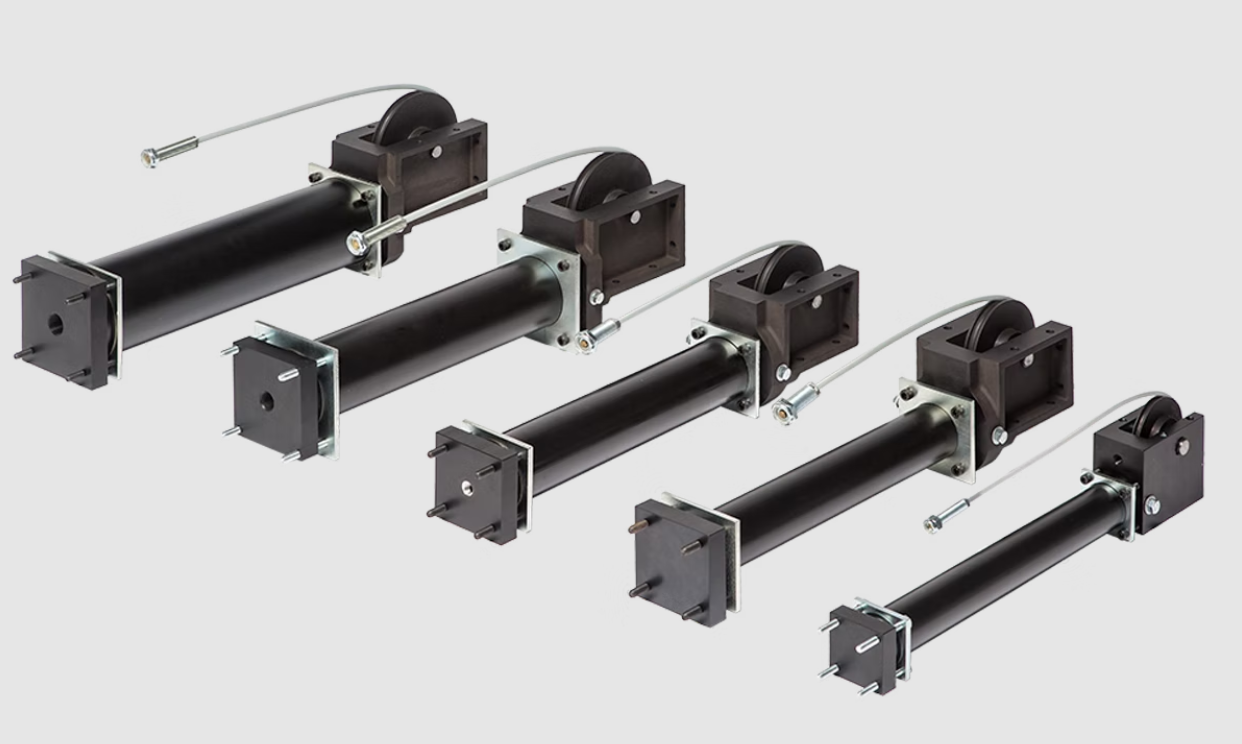

Pneumatic cylinders, such as MAGTEC®, pneU-SA®, and DURATRK™, can be modified so that the band is inverted, allowing the use of a custom arm that exerts the same force on both sides. Cable cylinders and OVLPRO™ rodded cylinders are often preferred for their availability, performance, and cost-effectiveness. Selecting the right configuration is crucial for optimal performance in diverse applications.

Distinguishing Between Single- and Double-Acting Hydraulic or Pneumatic Cylinders

Understanding the fundamental differences between single- and double-acting cylinders is essential for designing efficient systems. Hydraulic cylinders (powered by fluid systems) are known for heavy lifting, while pneumatic cylinders (powered by air systems) are more cost-effective and agile and are more widely used in industrial applications.

How a Double-Acting Pneumatic Cylinder Works

Compressed air is forced into the port at one end of the cylinder to push the piston forward, then into the opposite port to push the piston back. The alternating pressure moves the load a specified distance and then automatically retracts the piston for the next forward stroke. This process can be accomplished with a simple on-off control valve.

How a Double-Acting Hydraulic Cylinder Works

Hydraulic fluid is pumped into one port to extend the piston, then pumped into the opposite port to return the piston to its original position. This is essentially the same as for the pneumatic cylinder, except that the two service lines carry hydraulic fluid instead of compressed air.

Advantages of Single-Acting Hydraulic or Pneumatic Cylinders

A single-acting cylinder is simpler, so there is less to maintain. With only one sided being active, the action of the cylinder is determined entirely by the pressure on one input port. They often have a spring or similar internal device to push or retract the piston rod, but they might rely on the force on the other end to push it back. Simplicity is always good for equipment that needs to be rugged and reliable.

Advantages of Double-Acting Hydraulic or Pneumatic Cylinders

A double-acting cylinder alternates cycles of pressurized fluid to both sides of the piston and creates extend and retract forces to move the piston rod, permitting more control over the movement. Using a control system made up of a 2-, 3-, 4- way position valve would be required to achieve the desired movement for your application.

Control Considerations

The choice between single- and double-acting cylinders boils down to the level of control required. Single-acting cylinders suffice for one-directional tasks, while double-acting cylinders are essential for applications demanding precise control in two directions.

Double-acting cylinders prove to be versatile workhorses, catering to a myriad of applications across industries. Whether you need efficiency in cutting paper rolls or precision in silk-screening, the right configuration of double-acting cylinders ensures optimal performance.

Understanding the distinctions and advantages of single- and double-acting cylinders is crucial for designing systems that meet specific application requirements. If you're unsure about the best configuration for your needs, consult with our technical experts at Branham for personalized assistance in finding the perfect solution for your motion control challenges.