Branham product lines continue to expand because industrial and manufacturing equipment continues to evolve. Issues such as limited space or the need for ever-more-efficient operation drive product improvements, resulting in innovations such as our PFS38 Series pneumatic spring-applied fail-safe brake.

Pneumatic spring-applied brakes offer a number of advantages in industrial settings. They run on standard shop air, which is commonly available, giving you reliable power for emergency braking or holding without the need for a hydraulic system. That’s simpler and less costly. Pneumatic spring-applied fail-safe brakes are also ideal for clean environments where hydraulic systems would be inappropriate.

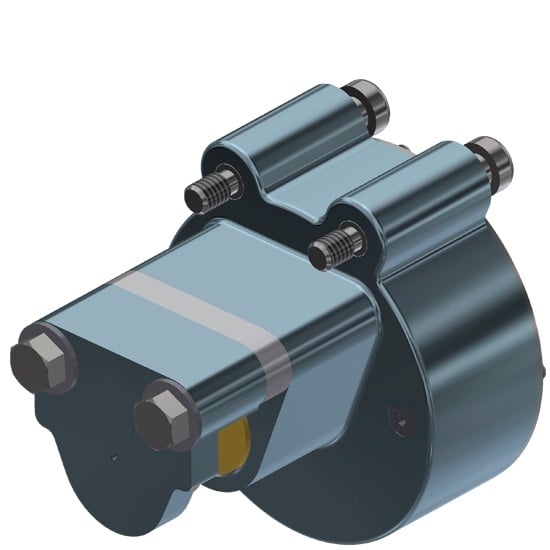

We offer pneumatic fail-safe brakes in a wide range of clamping force and release pressure options. However, not all applications require large braking force. The PFS38 is our smallest model – designed for situations where less force is needed or space is limited.

Fail-Safe Brakes Play Two Vital Roles

- Emergency (dynamic) stop and hold

This is the true fail-safe scenario. For example, with a web press or similar operation, there is a rotating disc on a shaft. But you don’t want the equipment to continue rotating if pressure is not available to control it. This is a critical safety precaution that automatically activates to stop equipment if power is lost or pressure drops below a specified threshold. Without this backup, malfunctioning equipment could seriously damage machinery or the process underway, or endanger people nearby.

- Production line stop-and-hold

This is a standard holding brake function, where the brake is engaged to hold an object on a production line. For example, there may be two posts that support a guillotine above the line, with brakes on the post to hold the knife and then release it at specified intervals to drop or move as required. This is common in punching, cutting, and drilling operations. Or, the elbow of a robotic arm may need to move to a certain angle and then hold in place–a pneumatic spring-applied brake such as the PFS38 is ideal for this.

PFS38: Right-Sized for Smaller Applications

Our goal at Branham is to ensure our customers always have the best options–the right combination of components to optimize equipment design and function in a particular application. The PFS38’s compact size can be a significant benefit when design space is limited–an increasing issue in many industries where the equipment itself is getting smaller.

However, you also have to consider the required tangential force to know which brake configuration is best. For example, using the small PFS38 brake with a large disc may provide the same force as using the next-larger PFS47 with a smaller disc.

PFS38 specifications:

- 85 psi release pressure

- Single Belleville disc spring stack

- 216 lb. maximum tangential force at zero friction pad wear

- 3350 in. lbs. F. using 30-inch disc diameter at maximum tangential force

- Maximum 480 lb. clamping force

- Unlimited disc diameter (2.00 sq. in. total friction pad area)

- .46 cu.in. wearable friction material

- 3.25 in. piston diameter

- 2.4 lb. brake weight

There are four standard models in the PFS38 series:

- 4005-0200/PFS38AF (.156 in. disc thickness)

- 4005-0201/PFS38BF (.250 in. disc thickness)

- 4005-0202/PFS38LF (.375 in. disc thickness)

- 4004-0203/PFS38EF) (.500 in. disc thickness)

How Fail-Safe Brakes Work

Pneumatic spring-applied fail-safe brakes are single-active (single-sided), where the pad floats over the disc or rail. When pressure is released, the active side presses the pad against the disc (or rail), pulling it against the inactive side for clamping. The PFS38 uses a single Belleville spring stack to store energy which is then released to drive the braking action. Larger models use multiple spring stacks to achieve the required tangential force.

Belleville springs have specific tolerances, which dictate the amount of pressure required to overcome the force produced by the spring. Therefore, it may take 80-90 psi of pressure for release. We call out 85 psi as an average, which is well within typical shop air availability.

Braking torque also depends on disc size: torque = tangential force x braking radius

For example, the braking radius on a 10 in. disc is about 4 in. If you need more torque, you can increase the amount of tangential force or increase disc size. If the amount of required tangential force is small enough, you could use a PFS38 with a smaller disc.

Braking Torque at Various Disc Diameters chart here

Whether you choose the PFS38 or a larger model, proper maintenance protects both brake performance and life. Monitoring pad wear is particularly important.

Belleville springs are flat when compressed but conical when released, so there is a specific stroke length associated with each size spring. The maximum force exerted lies at a certain point along that stroke, and the brake is designed to optimize that force. However, as the brake pad wears, it gradually increases the spring’s stroke, reducing available braking force.

In a holding application, there should be zero pad wear. In dynamic scenarios, though, it’s important to know the point at which pad wear will diminish force and, therefore, performance. It’s a straight-line decline, with a 1:1 decrease in tangential force. The PFS38 starts at 216 lb. then drops to 162 lb. at 0.06 in., then to 108 lb. at 0.12 in., and so on.

You know how much tangential force you need as well as the minimum pressure threshold you need to maintain. Knowing how pad wear relates to force loss makes it easy to monitor pad wear according to the chart to see the optimal point to replace the pad.

Built for Reliability and Durability

Like all Branham pneumatic spring-applied brakes, the PFS38 series features:

- Cast aluminum housing

- Anodized components that have a protective, hardened coating which also ensures pistons are better-sealed

- Non-asbestos friction material

- Replaceable friction pads

- Buna-N seals

- Float mount

- Belleville spring stack(s)

- .45 coefficient of friction

- 100 psi maximum pressure

Options include:

- Viton® seals

- Electro-nickel plating

- Stainless steel hardware

- Fitment for metric brake disc sizes

Fail-safe brakes perform critical duty in industrial settings. Our team here at Branham can help you determine which model and size will give you optimal backup and confidence.