Industrial equipment and mobile machines serve a wide variety of purposes, and they work under a wide range of conditions. Regardless of a machine's specific function, however, equipment that moves also has to slow and stop – sometimes repeatedly and frequently. There is a braking system to fit every set of variables. Some are mechanical or pneumatic, but for certain applications (which often require greater braking force), hydraulic brakes are your best choice.

Mechanical brakes are the simplest, requiring no outside power source to operate. Pneumatic brakes (or air brakes) can be a convenient, efficient choice, where there is no hydraulic pressure source and the application is sufficient for a pneumatic brake with a pressure source of 100 psi or lower. So when it comes down to air vs. hydraulic brakes, Hydraulic brakes can be the most effective choice when your application requires high torque stopping, tensioning, or holding.

Common examples include on- and off-road vehicles, mining and oil field operations, and wind turbine brakes in the 50kw class.

How Hydraulic Brakes Work

Hydraulics use fluid to apply the pressure that causes slowing or stopping. Some types use DOT 3 or DOT 4 automotive brake fluid, which is polyethylene glycol. DOT 3 is more common, has a lower boiling point, will absorb less water, and generally needs to be changed less often. DOT 4 brake fluid is better suited for higher temperature applications.

Other brakes use industrial hydraulic oil. The amount of pressure applied (and in relation to the brakes' piston bore area) determines how tightly the system compresses rotating parts. Hydraulic brakes tend to be used in higher-pressure applications. Be sure to specify the fluid type you require to ensure your brake is equipped with compatible seals.

Double-acting hydraulic brakes compress the rotor (or linear plate) from both sides. With floating hydraulic brakes, the brake pad on one side is fixed, and compression is applied from the “live” side. The brake "floats" when the live side is pressurized, moving the fixed side to the opposite rotor face, applying equal braking torque or clamping.

Hydraulic brakes can perform all three types of potential braking needs:

- Dynamic, or active, braking – bringing a moving part to a full stop. This applies to all types of vehicles, including construction equipment and wind turbines.

- Holding – stopping a moving part mid-way through an action, such as a winch on a crane or a cable wheel on a utility vehicle.

- Tensioning – controlling the speed of a moving part by exerting drag rather than stopping it altogether. This may come into play with any application, but it is critical for production applications that use web systems to handle rolls of material such as newspaper, tape, foil, etc.

Another form of hydraulic brakes are the spring design. Hydraulic spring applied brakes often get used in industrial applications where emergency stopping and holding is required. These types of brakes work somewhat in reverse. When a minimum hydraulic pressure is deployed, the brake piston is pulled away from what it’s meant to brake. Then, at a loss of hydraulic pressure, the energy stored in the spring is released and the brake piston engages for positive stopping force.

READ: How Hydraulic Spring Applied Brakes Help Abrahamson Nurseries Work Safer

If your application requires the higher braking force of hydraulic, but you only have access to air pressure, an Air/Oil Intensifier may be an option.

Advantages of Hydraulic Brakes

Hydraulic systems are powerful enough to handle industrial applications that require frequent start-and-stop cycles. Or applications where heavy flywheels or rotating shafts must be stopped within a specific time period, sometimes just a split-second. The hydraulic fluid absorbs much of the heat produced by these actions, causing it to degrade over time, but it is easy to replace.

Hydraulic brake systems also enable the greatest design flexibility, because the hoses that carry brake fluid are small and made of flexible plastic, making it easy to route them as needed. In applications where hydraulic hoses need extra protection, the hose is covered with braided wire.

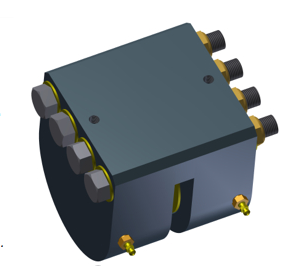

W.C. Branham offers a tremendous selection of hydraulic brakes as well as an easy-reference chart that lists each product by name and number, gives a brief description, indicates the disc thickness, and the type of hydraulic fluid required. We also offer pneumatic and hydraulic spring applied and hydraulic/mechanical brake combinations for many different types of applications.