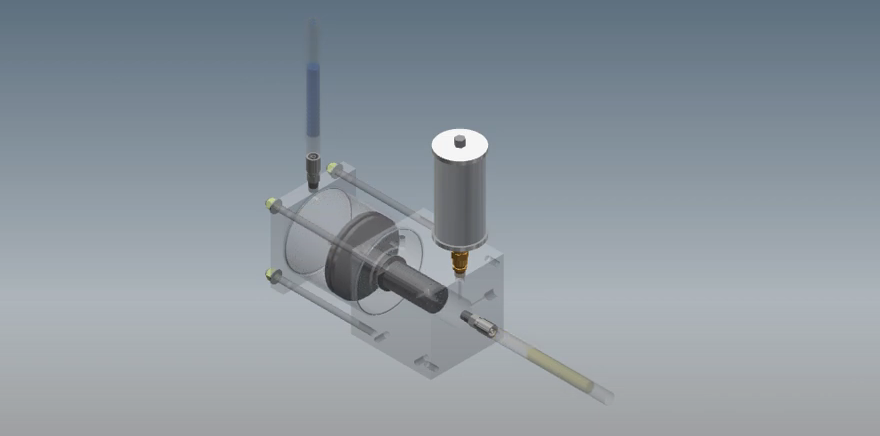

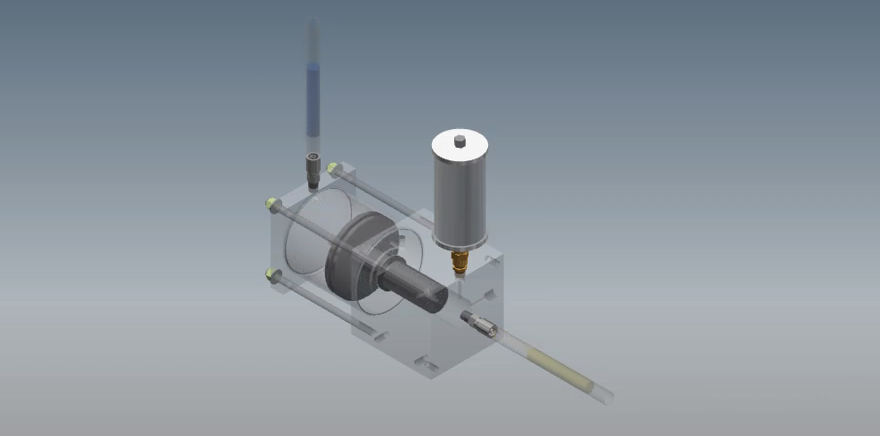

Pneumatic cylinders are versatile workhorses when it comes to moving and holding loads. But there are times when a certain task requires enhanced pressure or stability beyond what a single pneumatic actuator can produce. Air over oil intensifiers solve this problem by producing on-demand hydraulic pressure where needed when compressed air is the only generalized power source.

In an intensifier, there are two chambers. In the first, pneumatic pressure drives a piston which pressurizes the hydraulic chamber to create the greater overall pressure required to perform the task. The system is self-contained, so there is no need to install additional hoses or related equipment.

Intensifiers are intriguing for many different applications. They are capable of producing a wide range of conversion ratios, so resulting pressure can be far greater than the 80-100 psi typically available with shop air. Here at Branham, we offer options from 5:1 to 36:1.

These units work with standard or spring-applied hydraulic brakes. They are extremely versatile, ideal in any situation where you have small hydraulic devices that do not require high-volume fluid displacement. They are often used for braking applications, but our customers use them for everything from grippers and indexers to winding machines, robotics, and more.

Creative Uses for Air Over Oil Intensifiers

Clamping and Holding: The high pressure generated by air over oil intensifiers makes them suitable for clamping and holding applications in manufacturing and assembly lines.

Testing and Calibration: These devices are employed in testing and calibration equipment where precise and controlled hydraulic pressure is required to evaluate the performance of other hydraulic systems or components.

Safety and Emergency Systems: In some applications, air over oil intensifiers are used in safety systems or emergency braking systems where a rapid hydraulic response is required.

It's important to note that the specific applications may vary depending on the design, capacity, and features of the air over oil intensifier, and the technology continues to find new uses as industries innovate and develop new processes.

Can I Use More Than One Intensifier?

Yes, using multiple intensifiers increases the amount of fluid displacement as long as the units are run in parallel. An intensifier is not rated for units to be run in a series. It is best to consult with our Branham team when looking to use multiple intensifiers.

What If I Need Higher Fluid Displacement?

As we stated above, you can achieve a higher fluid displacement using multiple intensifiers. But before committing to this option, take a look at our OVLBOOST intensifier. These units are designed specifically to address fluid displacement on a more affordable scale. It is a hybrid pneumatic-to-hydraulic actuator that is longer on the hydraulic side to accommodate greater displacement. The OVLBOOST works with our oval bore extrusion, allowing for a lower profile and producing a pressure ratio of 7.8:1. If neither of these options work and you have quantity potential, you may need to consider a custom design to fit your needs.

Air over oil intensifiers give you options to achieve maximum equipment and facility design. Need expert advice about incorporating them into your project? Ask away! We’re just a phone call or email away.