Rodless cylinders save space. Whereas a rodded cylinder needs at least twice its stroke length to accommodate extension of the rod, a rodless cylinder is entirely contained within its housing. Since the envelope can be smaller, you can get more stroke in less space. That’s a tremendous advantage in any manufacturing or industrial setting where space is at a premium. It may even be the factor that makes your equipment or system design possible.

Rodless cylinders are also impressively versatile–useful in applications as diverse as corrugated paper splicing to car wash systems, animated displays to parts elevators.

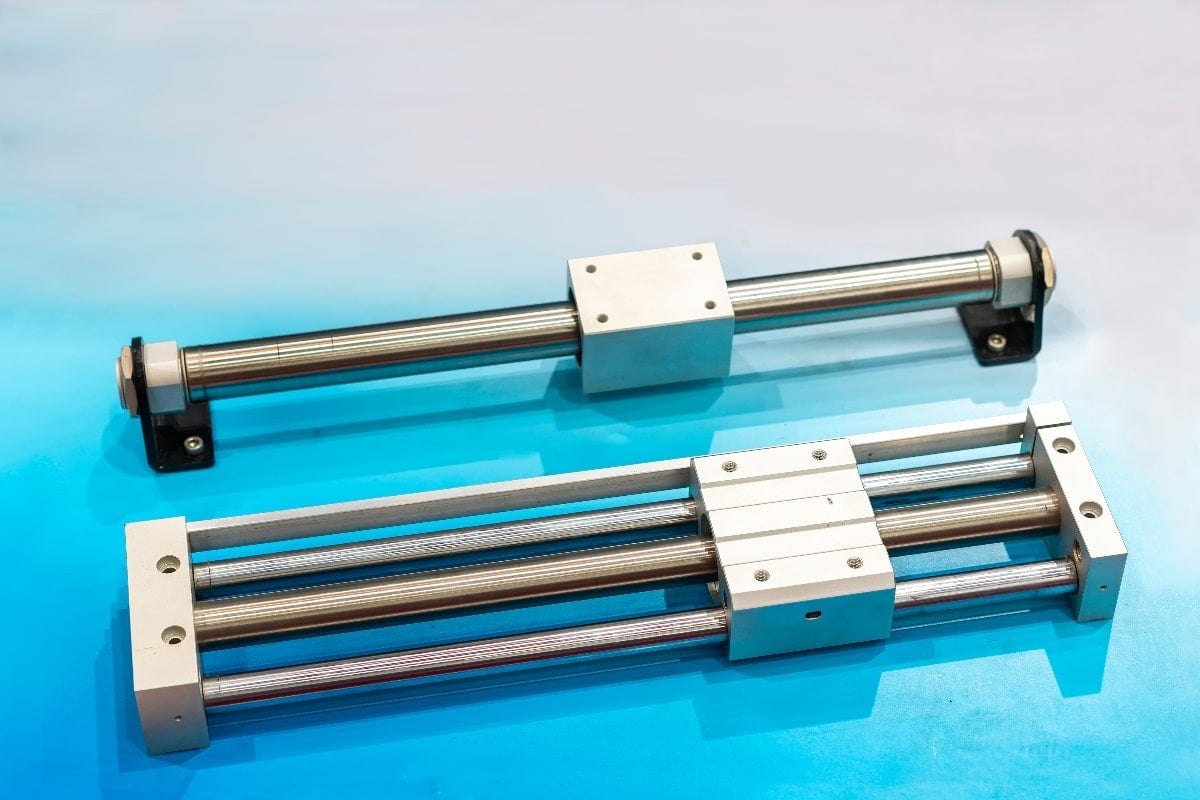

Different Styles for Different Needs

You can use rodless cylinders in applications that require long stroke lengths–for example, transferring loads over longer distances (multiple feet as opposed to a few inches). This is one of the greatest advantages of rodless cylinders because many rodded cylinders can only function up to a certain length before the rod will deflect and bow. Double-acting rodless cable cylinders enable long stroke lengths, up to 40 feet in some instances.

Magnetically coupled cylinders are entirely enclosed, making them ideal for harsh or high-sanitation environments.

Different applications feature different moment loads. Certain types of rodless cylinders are rated for different moment loads, so they can be used as both guide and actuator. Therefore, when the cylinder can take on whatever moment loads are required, that makes system design and operation more flexible.

Despite all these benefits, rodded cylinders are much more common in most applications. But could that change in the future?

Manufacturing is Growing, but Also Getting Smaller

It’s not your grandfather’s manufacturing industry anymore. Supply chain and logistics woes highlighted by the pandemic and growing desire to cut dependency on China are leading a manufacturing boom here in the US. Bloomberg reports construction is up 116% just in the past year, and they say the re-shoring movement “creates opportunities for the smaller manufacturing companies.”

Yes, huge new facilities are still being built–recently-announced semiconductor plants are a highly visible example. But there is also a growing trend toward smaller footprint facilities. Increasing use of automation and robotics in manufacturing make production more efficient and require less overall space. High real estate and construction costs make efficient use of space critical for every manufacturer, especially smaller operations.

Rodded cylinders will always make the most sense when loads need to move only a few inches. But when you need a longer stroke–perhaps many feet–and space is limited, a rodless cylinder can solve your problem.

What’s the best cylinder for your space and application? Our Branham engineering experts are here to help answer questions and guide you toward the most effective and cost-effective solution. Just give us a call.