When your machine needs to transfer power between shafts that intersect at odd angles—or don't intersect at all—standard gears won't cut it. You need a more sophisticated solution.

That's where bevel gears come in, keeping operations moving smoothly across countless industrial applications and vehicles worldwide.

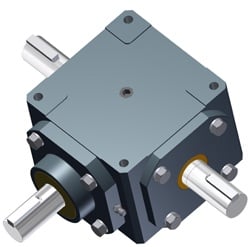

Understanding Your Bevel Gear Options

Bevel gears have conical pitch faces. The angle between this pitch face and the mounting axis determines the pitch angle, which can be worked to meet your specific needs. While many bevel gears operate at right angles (like a hand drill), they can be designed to function at any pitch angle for your application.

Types of Bevel Gears and Their Advantages

Each type of bevel gear offers benefits for different applications:

- Straight bevel gear: The most common type with straight, tapered teeth. Works well but can be noisy at high speeds or heavy loads.

- Spiral bevel gear: Curved teeth create gradual contact, resulting in quieter operation and less wear than straight bevel gears.

- Zerol bevel gear: Curved teeth that run parallel to the axis.

- Hypoid bevel gear: Offset design perfect for vehicle differentials and similar applications.

Real-World Applications Demanding Precision

Bevel gears show up in more places than you might think:

Wind Turbines

Those massive turbine blades turn slowly, but generators need high-speed rotation to produce electricity. Bevel gears bridge that gap, handling huge forces while keeping everything running smoothly. Spiral bevel gears are especially good at this job.

Cooling Towers

The big fans in industrial cooling systems never stop. They need bevel gears that can handle running 24/7 without breaking down. When downtime costs money, spiral bevel gears deliver the reliability you need.

Steel Manufacturing

Steel mills are tough on equipment. Bevel gears keep conveyors moving, power rolling mills, and drive cutting equipment—all while handling heavy loads and maintaining precise control.

Printing Presses

Getting perfect prints means keeping rollers well synchronized. Spiral bevel gears make this happen, maintaining alignment even at high speeds so every print comes out right.

Selecting the Right Bevel Gear for Your Application

Manufacturing spiral bevel gears was once extremely expensive and complex. Modern technology has made these components more accessible, but they still need expert manufacturing.

When selecting your gears, spiral bevel designs offer these advantages:

- Flexible positioning: Unlike offset shaft designs, spiral bevel gears deliver power directly where you need it, at any angle required.

- Minimal power loss: Precision manufacturing creates less than half a degree of backlash, ensuring efficient power transfer.

- Reduced noise: Teeth engage gradually rather than abruptly, eliminating the clacking common with straight-cut gears, especially under heavy loads.

- Lower maintenance costs: Quality manufacturing means less wear between teeth. Basic lubrication keeps them running reliably for years.

Making the Right Choice

For applications requiring high RPM, high torque, frequent load cycles, or speed reduction, spiral bevel gears typically provide the best solution. When you need to transfer power between shafts spinning at different speeds—such as in vehicle differentials—hypoid bevel gears offer optimal performance.

Choosing the right bevel gear matters. If you're building new equipment or upgrading what you have, the right gear selection means better performance and fewer headaches down the road.

If you have questions about choosing the right bevel gear design for your application, W.C. Branham's experts are ready to help you find the perfect solution.