Everything You Need to Know About Spiral Bevel Gear Design

Years ago, it was expensive and very difficult to make spiral bevel gearboxes. And while the precision necessary to craft such beautiful and intricate pieces is still tricky, technological advances in manufacturing make it much more doable.

Years ago, it was expensive and very difficult to make spiral bevel gearboxes. And while the precision necessary to craft such beautiful and intricate pieces is still tricky, technological advances in manufacturing make it much more doable.

There are actually four types of bevel gears: straight, spiral, zerol, and hypoid. They can:

- Control rotational speed

- Control torque

- Change rotational direction

In order to fully appreciate the many advantages of spiral bevel gearboxes, here is everything you need to know about their design.

Straight vs. Spiral Bevel Design

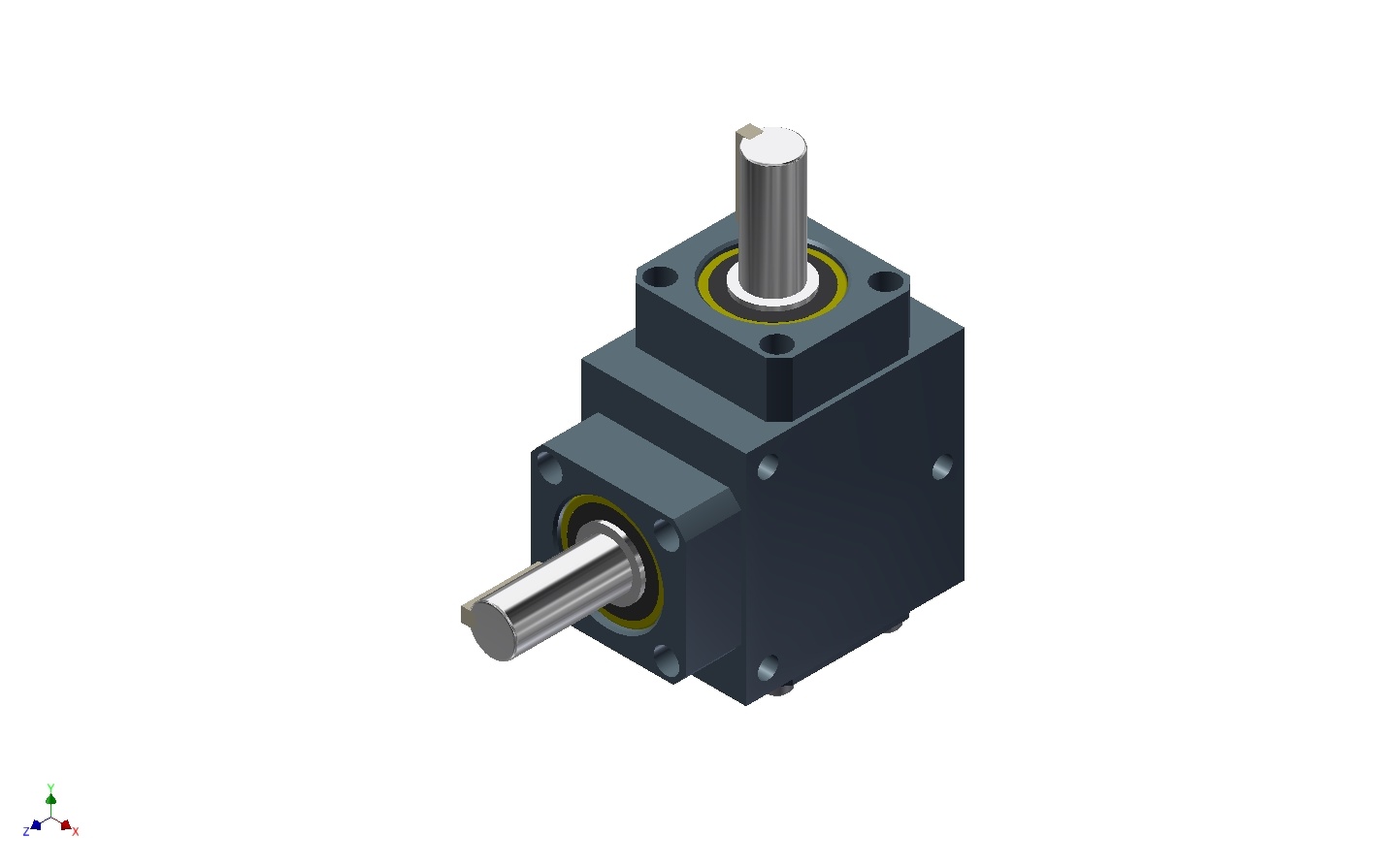

A bevel gear is conical in shape, with the specific pitch angle determined by the requirements of the operation. The surface has a series of teeth that come together to drive the cone as it rotates on a shaft. The teeth are arranged in parallel rows, either straight up and down or curved into a spiral formation.

This helix design is very complicated and intricate. Before computer-controlled machines, it took an expert machinist many hours to be able to craft gears like this from raw stock. The helical cut runs either clockwise (right hand) or counter-clockwise (left hand). For this reason, these gears have always been designed, fabricated, and used in pairs. A gearbox, once fabricated, should be considered sealed.

The most common form of spiral bevel gearbox is a differential, like that found in a car. This design is highly complex, allowing each wheel to turn at a different rate. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. However, even the simplest form of a right angle gearbox uses the same elegant spiral bevel gear cut, but with gears much more similar in diameter and number of teeth.

You can learn more about straight and spiral bevel gear design here. A bevel gearbox is not necessarily the only solution; however, it is often the better solution.

Certain spiral design features stand out and should be highly considered when deciding which gearbox to use in a new design.

Advantages of Spiral Bevel Design

- They are on-plane. In a hollow bore helical gearbox, the input and output shafts are offset vertically, so they cannot provide direct transfer of power at a right angle in the same plane. Spiral bevel gears are aligned on-plane, allowing them to operate at any pitch angle to deliver the power you need where you need it.

- They are precise. With less than half of a degree of backlash, there is little torque or power wasted in the slop of the gearbox. This inherent efficiency is a result of the intricate spiral bevel gear design which has to be made to very exacting specifications.

- They are quiet. The clacking sound of straight teeth as they meet can be very noisy, especially when the gear is operating under heavy loads or at high speed. With spiral design, the teeth meet gradually so operation is much quieter and more efficient.

- They have a long life. Because of the tight tolerances and gradual contact in a spiral bevel gear design, there is very little wear between the teeth. This gives them a relatively longer operating cycle with minimal maintenance other than basic lubrication.

Spiral design is especially valuable in applications that require high torque, high rpm, frequent load cycles, and/or when you need to reduce speed.

Putting Spiral Bevel Design to Work in Your Application

For all these reasons, the modern spiral bevel gear design is very much the system of choice for transferring power at a right angle. Where they were once very difficult and expensive to machine, today they are the standard method of choice for any application where power must be turned at a right angle. They are definitely the state of the art for any application of turning force today.

Need help selecting the right one for your needs? Just give us a call or drop us an email.