Choosing the Right Right Angle Gearbox

Every design engineer knows that you have to get all of the details right. If not, the device or equipment you’ve designed won’t perform as well as expected. That won’t do, especially when you’re designing for industrial applications.

With so many unique applications and different sizing requirements, it can be difficult to find the perfect gearbox for your needs. In this video, our VP of Engineering and General Manager, Chad Randleman walks you through the process of selecting and sizing a gearbox to meet your needs.

Types of Gearboxes

Right angle gearboxes are popular because they are versatile and offer great value for a wide range of industries and specific applications. However, that versatility can lead to confusion during the design phase.

W.C. Branham manufactures a broad array of right angle gearbox models, each designed to accommodate a variety of options. For example:

- Insert-A-Shaft® models are an ideal choice for packaging equipment. They come in a variety of different sizes, with bore centers from 1” to 2.5.” Models with hollow-core configuration allow the shaft to run through the gearbox bore. IAS gearboxes are available in both left and right-hand rotation, which determines the output shaft rotation in relation to the input.

- Continuous Recirculation Lubrication (CRL™) gearboxes are sealed so they never need fluid replenishment. They are a good choice for high-cycle or heavy-duty applications.

- Spiral Bevel models work best for high rpm and higher torque applications.

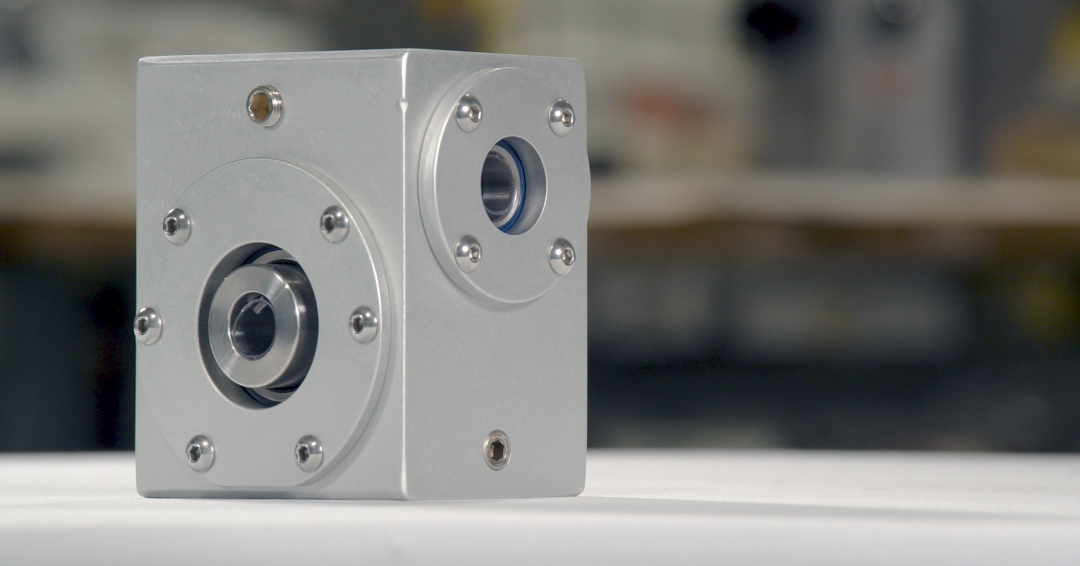

- MICROGEAR® boxes are the newest and smallest gearbox addition to our line. With either a .5 inch or .75 inch bore/shaft centerline, these gearboxes are designed to support today’s trend toward smaller devices and smaller production environments.

For specialty applications (such as food grade, pharmaceutical, and other washdown applications or other types of harsh environments) we offer gearboxes in either electroless nickel plating or stainless steel construction.

Sizing Your Gearbox

Right angle gearboxes can be configured and installed in multiple ways. However, it is essential to spec your gearcases correctly in order to achieve maximum performance. To properly size your gearbox, you will need to consider:

- Required output torque (or speed), along with RPM and shaft rotation

- Available space

- Configuration (2-way, 3-way, or 4-way)

- Bore centerline measurement

- Gear ratio

- Rotation configuration

Other key considerations for choosing the proper size gearbox include:

- Input horsepower and speed

- Supported or unsupported loads (if your gearbox will experience radial or axial loading, you’ll want to support the shafting externally using bearing blocks)

- Duty cycle = how long the gearbox will operate each day (gearboxes for light to moderate duty applications are considered lubricated for life while more severe duty applications should follow a relubrication schedule as part of regular maintenance)

- Special environmental conditions such as shock, vibration, corrosives

- Gear orientation (will the shafts protrude horizontally, vertically, downward?)

- Gearbox mounting requirements

Custom Design

Your goal is to design a right angle gearbox that will deliver both maximum performance and maximum durability. Despite the myriad configurations you can create with our different gearbox models and options, custom design can sometimes be your best option. It ensures that your design fits the application precisely, physically, and functionally.

You’ll likely have more questions, so just click here to connect with our experts. Collaborating with our design and engineering team will save you time and help you avoid common mistakes so you get exactly the right gearbox for your application.